Steel 30NCD16 - 1.6747 - 30NiCrMo16-6 - FE-PL2107 - 30Ni4CrMoA

30NCD16 structural steel is often used in the aerospace, automotive, and civil engineering industries - any sector where components are subject to high stress. This alloy can withstand heavy loads and extreme conditions without deforming or cracking, ensuring reliability and durability of the structures and components in which it is used.

Available shapes :

Order 30NCD16 Online

Select the desired form, standard, or specification and place your order with one click. A member of our sales team will contact you promptly to finalize your order.

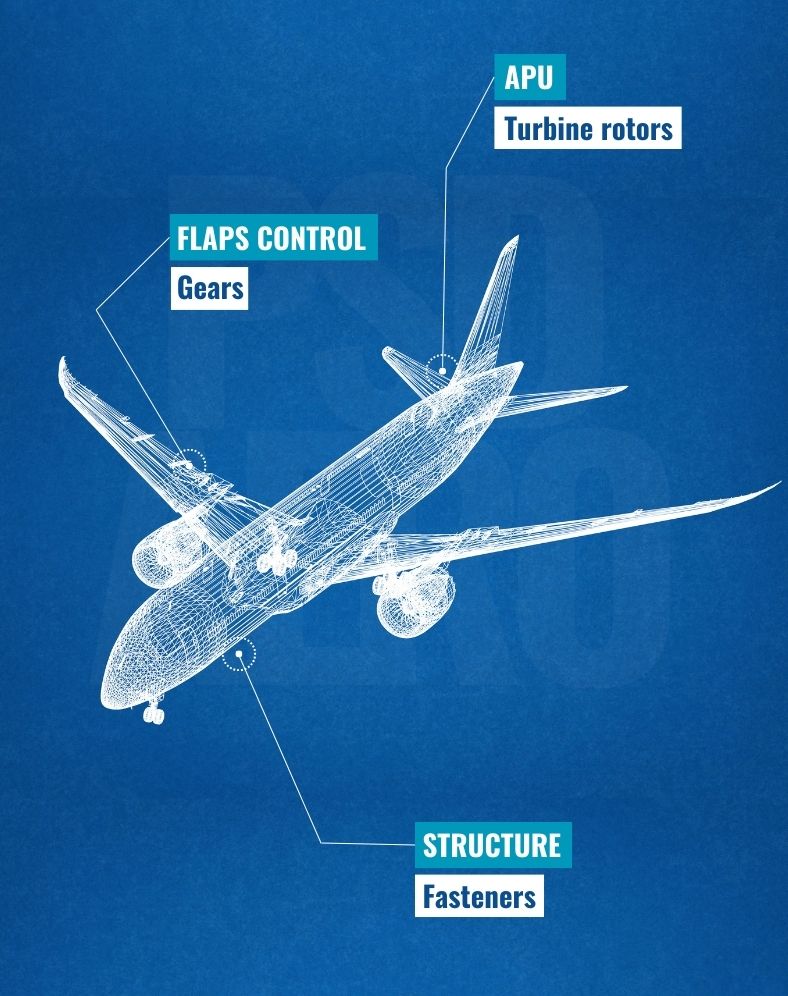

High-Strength Steel Alloy in Aeronautics

30NCD16 (or 1.6755) is a steel alloy containing chromium, nickel, and molybdenum. It is comparable to other steels like 35NCD16, which shares a similar chemical composition and mechanical properties but is optimized for specific uses. Like 35NCD16, 30NCD16 is often used in the aerospace and automotive industries for components requiring high strength and durability under fatigue and impact, such as gears, turbine rotors, and fasteners.

This steel alloy can undergo various heat treatments to enhance its mechanical properties: annealing, quenching, and tempering. Annealing aims to reduce hardness and improve machinability, while quenching and tempering increase hardness and mechanical strength.

Chemical composition of 30NCD16

The variations in its chemical composition for aerospace.

| % | C Carbon | Cr Chromium | Mn Manganese | Mo Molybdenum | Ni Nickel | P Phosphorus | S Sulfur | Si Silicon |

|---|---|---|---|---|---|---|---|---|

| Min. | 0.26 | 1.20 | 0.20 | 0.30 | 3.30 | <0.00 | <0.00 | 0.10 |

| Max. | 0.33 | 1.50 | 0.60 | 0.60 | 4.30 | 0.025 | 0.020 | 0.40 |

Related steel alloys

12NC12, FE-PL61

ROUND BAR

15CDV6, 15CrMoV6, 1.7734, 1.7736, AIR 9160

SQUARE BAR, RECTANGULAR BAR, ROUND BAR, WIRE, SHEET, ROUND TUBE

16NCD13, 1.6657, 14NiCrMo 13-4

ROUND BAR

25CD4S, 1.7218, 25CrMo4, FLE-PL1502

RECTANGULAR BAR, ROUND BAR, SHEET, SQUARE TUBE, ROUND TUBE

300M, A646, K44220

SQUARE BAR, ROUND BAR

30CD12, 1.8515, 30CrMo12, 31CrMo12, FE-PL1501

ROUND BAR

30CND8, 1.6580, 30CrNiMo8

ROUND BAR

32CDV13, 1.8522, 33CrMoV12, FE-PL1504

ROUND BAR

35CD4, 1.7220, 34CrMo4, 35CrMo4, FE-PL1503

ROUND BAR, ROUND TUBE

35NC6, 1.5815, 35NiCr6, FE-PL2102

SQUARE BAR, HEXAGONAL BAR, RECTANGULAR BAR, ROUND BAR, WIRE

35NCD16, 1.6773, 36NiCrMo16, FE-PL2108

SQUARE BAR, RECTANGULAR BAR, ROUND BAR

40CAD6-10

ROUND BAR

40CDV12, 40CrMoV12, FE-PL1507

PROFILE

40NCD7, 40NiCrMo7

ROUND BAR

42CD4

ROUND BAR

45SCD6

ROUND BAR

C75S

SHEET

DC04, Fe P04, St 14, ES

SHEET

E15CDV6

ROUND BAR, SHEET

E16NCD13

ROUND BAR

E32CDV13

RECTANGULAR BAR, ROUND BAR

E35NCD16

ROUND BAR

E40CDV12

ROUND BAR

E4330, 4330 Mod, A646 Grade 5

ROUND BAR

FER PUR

SHEET

GENRE STUB

ROUND BAR

S145F

SQUARE BAR, RECTANGULAR BAR

S145H

ROUND BAR

S534

SHEET

S97D

ROUND BAR

S98D

ROUND BAR

S99

ROUND BAR

X210CR12

ROUND BAR

X30Cr13, Z30C13

ROUND BAR

XC18S

ROUND BAR, SHEET, ROUND TUBE

XC38

ROUND BAR

Z230KDWVC11

ROUND BAR

Key properties

The most remarkable properties of this steel alloy

Tensile Strength

1080-1370 MPa

Impact Toughness

>550 kJ/m²

Yield Strength

>880MPa

Brinell Hardness

>270

How 30NCD16 is used in aerospace

The practical applications of this steel in aircraft construction.

Turbine rotors

Turbine rotors are present in Auxiliary Power Units and provide the necessary energy for the aircraft when it is on the ground. The wear resistance provided by 30NCD16 is suitable for rotors that spin very rapidly.

Gears

Gears enable the movement of flaps and landing gear. Subjected to constant friction, they must be wear-resistant: this is where the use of 30NCD16 comes in.

Fasteners

Fasteners (bolts, screws, etc.) maintain the structural integrity of aircraft, subjected to various load and stress conditions. 30NCD16 is particularly suitable here, making them resistant to impacts and vibrations.