Customized processing for our metal alloys

- Outsourcing processing needs

- More environmentally friendly practice

- Simplified inventory management

Quality control

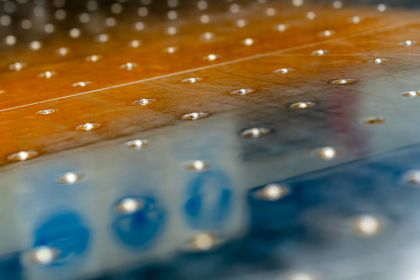

Each batch is continuously tracked within our warehouses through visual color identification and marking.

Extensive inventory

With over 10,000 product references distributed among 6 major metal families and 4 primary geometric shapes.

Large processing capacity

109+ machines at your disposal for custom cutting : band saw, laser / waterjet / plasma cutting, and many more.

Discover all our types of equipment and their capacities

Bandsaw machine

We have about twenty bandsaws in our warehouses, each with varying capacities. They allow us to achieve the following:

- Maximum diameter : 400mm

- Tolerance : 0/+3mm

- Automated continuous operation for 24 hours

- Bundle cutting at a speed of 15-125m/min

Vertical bandsaw

We have around ten saws that enable us to process cuts very quickly and with high accuracy :

- Maximum diameter: 530mm

- Cutting tolerance up to 0/+1.5mm

- Pulse cutting mode

- Automated continuous operation for 24 hours

Milling machine

Precise and modern, our milling machines have several options for automating processes.

- Maximum diameter: 75mm

- Maximum length: 2000mm

- Maximum tolerance: 0/+1.5mm

- Automated continuous operation for 24 hours or non-stop within the capacity of the bar feeder.

Disc saw

- Thickness: 2-170 mm

- Maximum length: 4200 mm

- Maximum width: 1600 mm

- Rotating table, cut optimization

- Tolerance: 0/+3 mm

Our circular saws are particularly suitable for cutting aluminum, which we process at GMAPSA, our Spanish site.

Slitter

Located at several of our sites, our slitting machines enable us to cover a wide range of materials for our customers.

- Throat depth: 380 mm

- Minimum strip width: 20 mm

- Maximum width: 4000 mm

- Length up to 3000 mm

- Tolerance: 0/+3 mm

- Integrated nesting capabilities

They cut all hard metals (cobalt, nickel, titanium, stainless steel, highly alloyed steel), as well as aluminum.

Waterjet cutting

Often combined with an abrasive material, high-pressure waterjets erode and cut through various materials. Due to the absence of heat generated during the cutting process, there are no thermally affected zones, which prevents material deformation or alteration of its properties.

- Max thickness: 175 mm

- Max length: 4000 mm

- Max width: 2000 mm

- Intensifier pump: 75 kW

- 2 cutting heads

Waterjet cutting is a high-precision cutting method that allows for complex and precise cuts.

4-axis vertical machining

4-axis vertical machining is a machining technique that uses a milling cutter to remove material from a workpiece. The "4 axes" refers to the four directions of movement available in the operation: the three linear axes X, Y, and Z, as well as a rotary axis that rotates around one of the linear axes.

- Travel (x, y, z): 1,630 mm, 762 mm, 650 mm

- Spindle: 20,000 RPM

- Automatic tool changer: 1.3 seconds

- Motor power: 18.5 kW

This configuration allows for greater flexibility in machining, enabling the production of parts with complex geometries and details. We use them for cutting steel and aluminum.

Shear

Shearing is a cutting method that uses a strong force to separate the material along the desired cut.

- Maximum length: 3000mm

- Maximum thickness for Inconel: 6mm

- Maximum thickness for stainless steel: 8mm

Generally used for cutting metal sheets to specific dimensions, we cut stainless steel and Inconel using our shears. The tolerances are lighter compared to other cutting methods, but the process is fast and cost-effective.

Vibratory finishing

Tribofinishing is a surface finishing method that utilizes friction between the workpieces and an abrasive media in a vibratory or rotating environment to achieve polishing, cleaning, or degreasing of the parts.

CNC lathes

Computer Numerical Control (CNC) lathes are machine tools that use computerized controls to perform turning operations on workpieces. The precision and reproducibility of operations are the main advantages of these lathes.

Turning capacity:

- Maximum diameter: 330mm.

- Maximum length: 3000mm.

Conventional lathes

Conventional lathes are manually controlled by an operator who adjusts the rotation speed, movement, and position of the cutting tool. They are less precise than CNC lathes but may be more suitable for certain tasks that require manual control.

Turning capacity:

- Maximum diameter: 330mm.

- Maximum length: 3000mm.

Brick-making device

A briquetting machine is an industrial equipment designed to convert waste materials into compact and uniformly shaped briquettes. Our aluminum briquettes are then recycled or reused in certain processes.

- Motor power: 30 kW

- Suction: 35 mbar

- Air volume: 9000 m³/h

- Sound level: 78 dB (A)