Steel 12NC12 - FE-PL61

Primarily composed of nickel and chromium, 12NC12 steel is used in aviation for components subjected to variable loads and constant friction. Thanks to its good wear resistance (or abrasion resistance), this alloy ensures the durability and performance of certain parts.

Available shapes :

Order 12NC12 Online

Select the desired form, standard, or specification and place your order with one click. A member of our sales team will contact you promptly to finalize your order.

A Wear-resistant steel

12NC12 steel (or 13Nicr 12) is commonly used in aviation for parts that need to withstand variable loads while being subjected to friction. These parts must therefore ensure good wear resistance, also known as abrasion resistance. The 12NC12 alloy in its carburized form has a hardened upper layer that makes it suitable for this type of use. In its non-carburized form, it is used for mechanical parts that do not particularly require wear resistance related to abrasion.

Chemical composition of 12NC12

The variations in its chemical composition for aerospace.

| % | C Carbon | Cr Chromium | Mn Manganese | Ni Nickel | P Phosphorus | S Sulfur | Si Silicon |

|---|---|---|---|---|---|---|---|

| Min. | 0.10 | 0.60 | 0.35 | 2.75 | <0.00 | <0.00 | 0.15 |

| Max. | 0.16 | 0.90 | 0.65 | 3.25 | 0.025 | 0.02 | 0.40 |

Related steel alloys

15CDV6, 15CrMoV6, 1.7734, 1.7736, AIR 9160

SQUARE BAR, RECTANGULAR BAR, ROUND BAR, WIRE, SHEET, ROUND TUBE

16NCD13, 1.6657, 14NiCrMo 13-4

ROUND BAR

25CD4S, 1.7218, 25CrMo4, FLE-PL1502

RECTANGULAR BAR, ROUND BAR, SHEET, SQUARE TUBE, ROUND TUBE

300M, A646, K44220

SQUARE BAR, ROUND BAR

30CD12, 1.8515, 30CrMo12, 31CrMo12, FE-PL1501

ROUND BAR

30CND8, 1.6580, 30CrNiMo8

ROUND BAR

30NCD16, 1.6747, 30NiCrMo16-6, FE-PL2107, 30Ni4CrMoA

SQUARE BAR, RECTANGULAR BAR, ROUND BAR

32CDV13, 1.8522, 33CrMoV12, FE-PL1504

ROUND BAR

35CD4, 1.7220, 34CrMo4, 35CrMo4, FE-PL1503

ROUND BAR, ROUND TUBE

35NC6, 1.5815, 35NiCr6, FE-PL2102

SQUARE BAR, HEXAGONAL BAR, RECTANGULAR BAR, ROUND BAR, WIRE

35NCD16, 1.6773, 36NiCrMo16, FE-PL2108

SQUARE BAR, RECTANGULAR BAR, ROUND BAR

40CAD6-10

ROUND BAR

40CDV12, 40CrMoV12, FE-PL1507

PROFILE

40NCD7, 40NiCrMo7

ROUND BAR

42CD4

ROUND BAR

45SCD6

ROUND BAR

C75S

SHEET

DC04, Fe P04, St 14, ES

SHEET

E15CDV6

ROUND BAR, SHEET

E16NCD13

ROUND BAR

E32CDV13

RECTANGULAR BAR, ROUND BAR

E35NCD16

ROUND BAR

E40CDV12

ROUND BAR

E4330, 4330 Mod, A646 Grade 5

ROUND BAR

FER PUR

SHEET

GENRE STUB

ROUND BAR

S145F

SQUARE BAR, RECTANGULAR BAR

S145H

ROUND BAR

S534

SHEET

S97D

ROUND BAR

S98D

ROUND BAR

S99

ROUND BAR

X210CR12

ROUND BAR

X30Cr13, Z30C13

ROUND BAR

XC18S

ROUND BAR, SHEET, ROUND TUBE

XC38

ROUND BAR

Z230KDWVC11

ROUND BAR

Key properties

The most remarkable properties of this steel alloy

Tensile Strength

830-1230 MPa

Impact Toughness

≥700 kJ/m²

Yield Strength

≥630 MPa

Brinell Hardness

≤217

How 12NC12 is used in aerospace

The practical applications of this steel in aircraft construction.

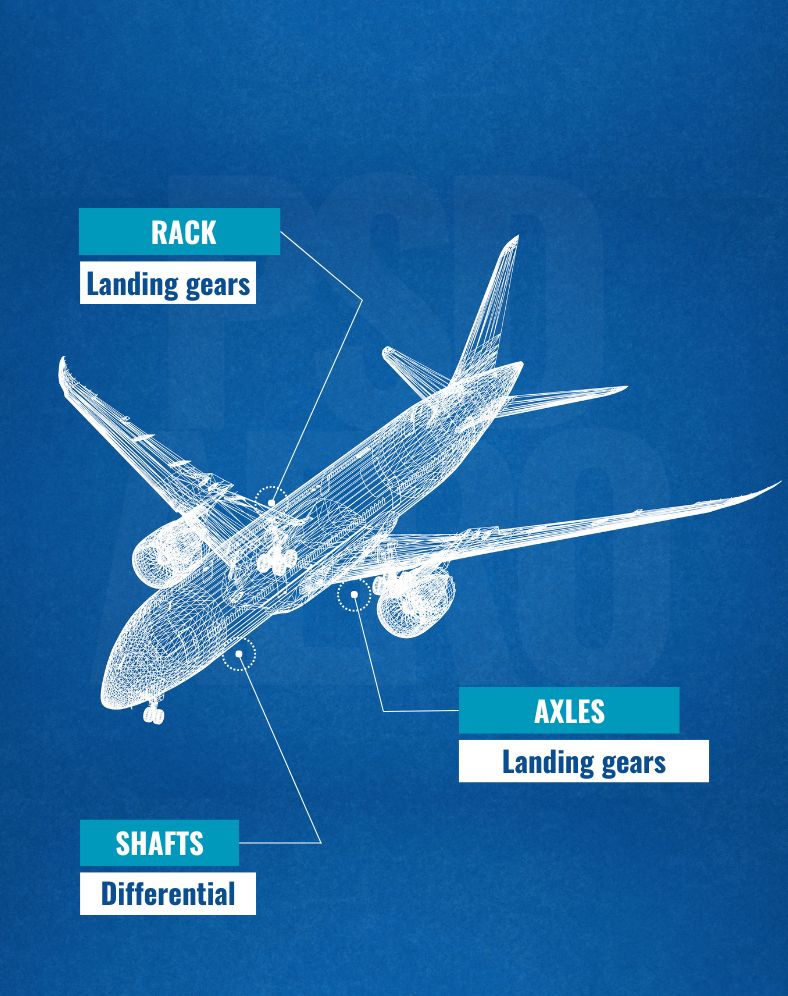

Axles

The 12NC12 alloy is used in the composition of certain airplane parts, such as axles. These axles support and transmit loads between the wheels and the structure of the aircraft: landing gear axles, wheel axles, or differential axles.

Landing Gear

In the landing gear itself, 12NC12 steel is also used for the rack. Located near the hydraulic actuators, this gear mechanism allows the landing gear of an airplane to be deployed or retracted.

Drive Shaft

In helicopters and some propeller-driven airplanes, the drive shaft connects the engine to the propeller(s): it passes through the firewall to reach the cabin. 12NC12 alloy provides it with good friction resistance.

Optimizing the use of 12NC12 : treatments, regulations, and options.

Explore our full range of steels in our online catalog

Order the grade you need

Applications of

12NC12 steel

How it is used in various industries.