Steel 300M - A646 - K44220

300M steel (developed in the 1950s by U.S International Nickel Co.) is a low-alloy, ultra-high-strength steel. Originally derived from 4340 steel for aerospace applications, the goal was to increase mechanical strength while maintaining excellent toughness. In practice, it is an AISI 4340 modified by adding silicon and vanadium, with slightly higher carbon and molybdenum content. It is also produced by vacuum arc remelting (VAR) to ensure purity and homogeneity.

Available shapes :

Order 300M Online

Select the desired form, standard, or specification and place your order with one click. A member of our sales team will contact you promptly to finalize your order.

300M, the result of optimizing the chemical composition of 4340

The designation “300M” is a commercial name that has become widespread. It is also referred to as AISI 4340M (modified 4340), sometimes written AISI E4340 Mod. Its UNS (Unified Numbering System) designation is K44220. It has no direct counterpart in the French/European standard but would correspond to a modified 40NiCrMo7 steel.

As seen earlier, 300M differs from conventional 4340 steel through its higher silicon content (~1.6 % vs ~0.25 % for a 4340) and the addition of a small fraction of vanadium (~0.05–0.1 %). Its carbon and molybdenum contents are also slightly higher than its predecessor.

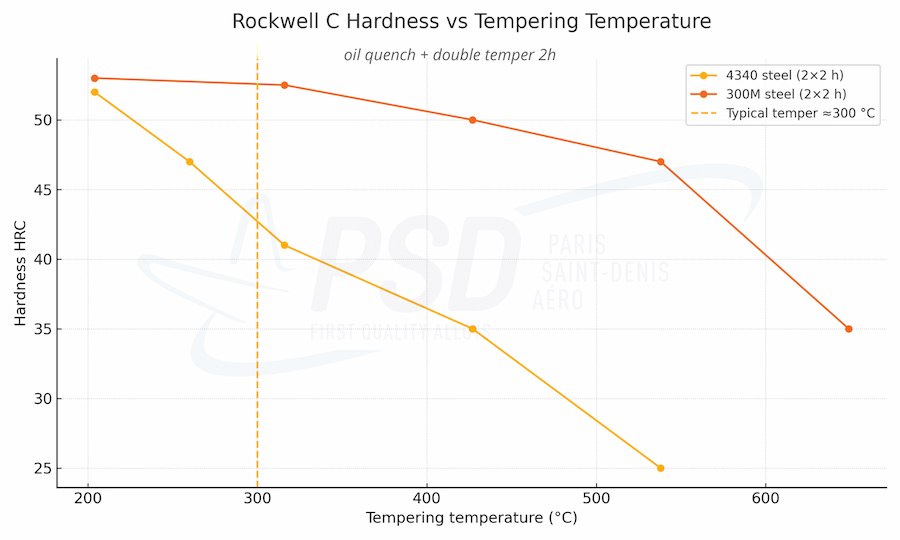

This composition is optimized for superior hardenability and core strength. Silicon at this level delays the tempering of martensite. By inhibiting the precipitation of cementite carbides (Fe3C) during tempering around 572 °F, it preserves very high strength, as illustrated by this diagram: [see schematic below, fig. 1]

- Up to ~572 °F, the hardness of both grades remains very high; 300M keeps a slight advantage (~1 HRC).

- Between 572 °F and 806 °F, 4340 starts to soften markedly (about 8 HRC loss), whereas 300M drops much more slowly (-3 HRC).

- Beyond 932 °F, the gap widens: 300M still retains ~47 HRC whereas 4340 falls to ~27 HRC.

Finally, the very small addition of vanadium refines the grain size during heat treatment (formation of V carbides/nitrides), improving both strength and toughness.

Mechanical properties of 300M, specialized in fatigue resistance

Like most ultra-high-strength steels, 300M shows no fatigue plateau indicating an absolute fatigue limit: the stress-versus-cycle curve continues to decrease beyond 10⁶ cycles.

In a more ductile steel such as 17-4 PH (condition H1025), local micro-plasticity blunts the tip of an emerging crack; the stress is redistributed and crack propagation arrests, giving rise to a fatigue limit. Nothing of the sort occurs in 300M, which is low-ductility and also has a low propagation threshold, so a micro-crack advances as soon as it experiences repeated loading.

Nevertheless, 300M was specifically designed to improve fatigue life over 4340 steel. It therefore provides excellent fatigue endurance, higher than that of 4340 under comparable conditions. Its cleanliness (thanks to vacuum melting) coupled with its fine tempered martensite give it good toughness, which slows crack growth and shifts the entire fatigue curve upward. Propagation thus remains slower than that of 4340 owing to its toughness and cleanliness.

Finally, like all high-strength steels, it exhibits limited work-hardening, and its elongation at break (7–8 %), although modest, is noteworthy given its high strength level.

Heat treatments of 300M, a through-hardened alloy

300M is a through-hardening alloy, with core hardness close to surface hardness. It requires meticulous heat treatment to develop its optimal properties; the slightest deviation can drastically reduce its performance.

Normalising and quenching

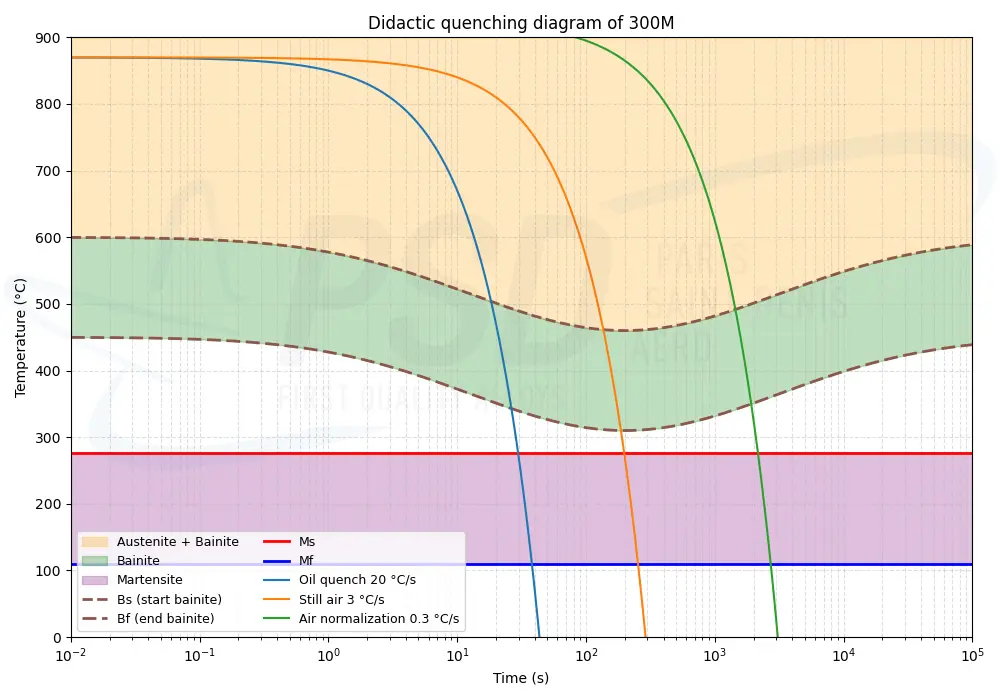

The green curve in the diagram above (fig.2) represents air cooling carried out at 1697 °F for 1 h after normalising. It homogenises the microstructure (uniforms the internal composition); the grain is refined and becomes more regular. The metal emerges with a fine microstructure, usually bainitic, ready for hardening. This heat treatment is used after hot forming or manufacturing 300M.

The orange and yellow curves (fig.2) represent two cooling methods after austenitising (1598 °F for 30 min to 1 h): respectively forced-air cooling (≈ 5.4 °F/s) and oil quenching (36 °F/s). This treatment heats 300M just enough to dissolve carbides, allowing alloying elements and carbon to enter solid solution in the new austenite structure. Because the high Si content increases the opposite tendency to decarburisation, it is carried out in a controlled or vacuum atmosphere to avoid it. Quenching is preferably performed in oil, immediately on leaving the furnace, to obtain martensite throughout the section. 300M shows excellent hardenability: even thick sections (~90 mm) can be through-hardened, achieving hardness above 50 HRC.

Double tempering

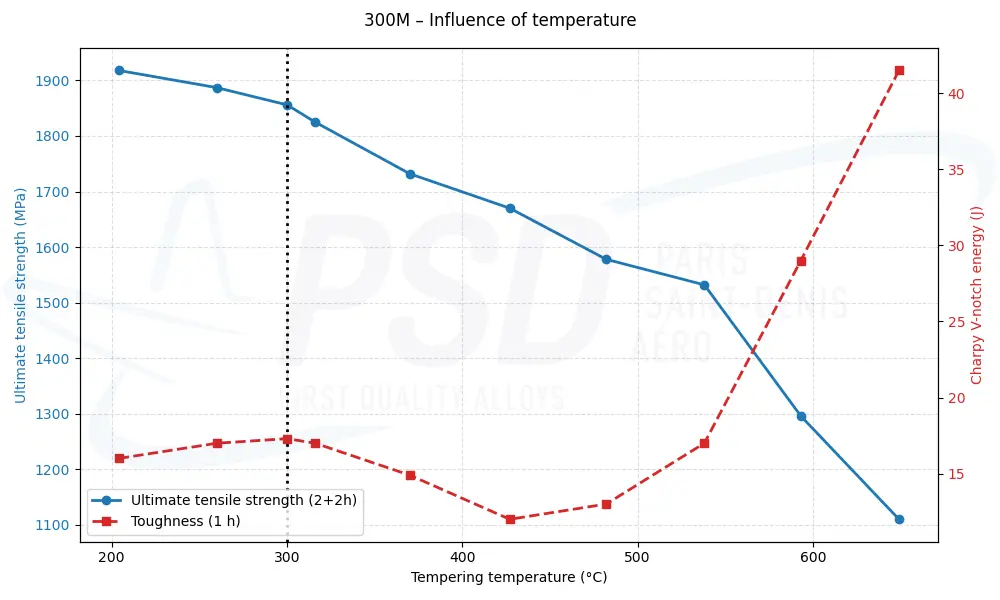

After quenching, double tempering is mandatory to relieve internal stresses, complete transformation of any retained austenite, and stabilise the result. A lower temper will yield slightly higher strength at the expense of toughness, while a higher one will reduce strength (and hardness) while increasing toughness (see fig.3 below). Precautions are necessary, however: 300M exhibits temper embrittlement between 662 and 1022 °F if the soak lasts too long or cooling is too slow. In aeronautics it is generally performed at 572 °F for 2+2 hours, giving a strength of about 1900 MPa with toughness satisfactory for critical parts such as landing gear.

Machining and welding

Machining must be carried out in the soft state (annealed or normalised). Welding is delicate because the alloy hardens readily in air, increasing the risk of cracking. It can be welded, by resistance or fusion, only with strict precautions (preheat, post-heat) and a subsequent heat treatment (re-normalising + temper) after welding.

In short, 300M steel is a benchmark material when excellent mechanical strength, good damage tolerance (cracks, impacts) and long service life are required. Its flagship historical applications are aircraft landing gear for both military and civilian aircraft, where it long remained the standard.

Chemical composition of 300M

The variations in its chemical composition for aerospace.

| % | C Carbon | Cr Chromium | Cu Copper | Mn Manganese | Mo Molybdenum | Ni Nickel | P Phosphorus | S Sulfur | Si Silicon | V Vanadium |

|---|---|---|---|---|---|---|---|---|---|---|

| Min. | 0.40 | 0.70 | <0.00 | 0.65 | 0.35 | 1.65 | <0.00 | <0.00 | 1.45 | 0.05 |

| Max. | 0.45 | 0.95 | 0.35 | 0.90 | 0.50 | 2.00 | 0.010 | 0.010 | 1.80 | 0.10 |

Related steel alloys

12NC12, FE-PL61

ROUND BAR

15CDV6, 15CrMoV6, 1.7734, 1.7736, AIR 9160

SQUARE BAR, RECTANGULAR BAR, ROUND BAR, WIRE, SHEET, ROUND TUBE

16NCD13, 1.6657, 14NiCrMo 13-4

ROUND BAR

25CD4S, 1.7218, 25CrMo4, FLE-PL1502

RECTANGULAR BAR, ROUND BAR, SHEET, SQUARE TUBE, ROUND TUBE

30CD12, 1.8515, 30CrMo12, 31CrMo12, FE-PL1501

ROUND BAR

30CND8, 1.6580, 30CrNiMo8

ROUND BAR

30NCD16, 1.6747, 30NiCrMo16-6, FE-PL2107, 30Ni4CrMoA

SQUARE BAR, RECTANGULAR BAR, ROUND BAR

32CDV13, 1.8522, 33CrMoV12, FE-PL1504

ROUND BAR

35CD4, 1.7220, 34CrMo4, 35CrMo4, FE-PL1503

ROUND BAR, ROUND TUBE

35NC6, 1.5815, 35NiCr6, FE-PL2102

SQUARE BAR, HEXAGONAL BAR, RECTANGULAR BAR, ROUND BAR, WIRE

35NCD16, 1.6773, 36NiCrMo16, FE-PL2108

SQUARE BAR, RECTANGULAR BAR, ROUND BAR

40CAD6-10

ROUND BAR

40CDV12, 40CrMoV12, FE-PL1507

PROFILE

40NCD7, 40NiCrMo7

ROUND BAR

42CD4

ROUND BAR

45SCD6

ROUND BAR

C75S

SHEET

DC04, Fe P04, St 14, ES

SHEET

E15CDV6

ROUND BAR, SHEET

E16NCD13

ROUND BAR

E32CDV13

RECTANGULAR BAR, ROUND BAR

E35NCD16

ROUND BAR

E40CDV12

ROUND BAR

E4330, 4330 Mod, A646 Grade 5

ROUND BAR

FER PUR

SHEET

GENRE STUB

ROUND BAR

S145F

SQUARE BAR, RECTANGULAR BAR

S145H

ROUND BAR

S534

SHEET

S97D

ROUND BAR

S98D

ROUND BAR

S99

ROUND BAR

X210CR12

ROUND BAR

X30Cr13, Z30C13

ROUND BAR

XC18S

ROUND BAR, SHEET, ROUND TUBE

XC38

ROUND BAR

Z230KDWVC11

ROUND BAR

Key properties

The most remarkable properties of this steel alloy

Ductility

≥4%

Tensile Strength

1930-2068 MPa

Yield Strength

≥1586 MPa

Brinell Hardness

≤99

How 300M is used in aerospace

The practical applications of this steel in aircraft construction.

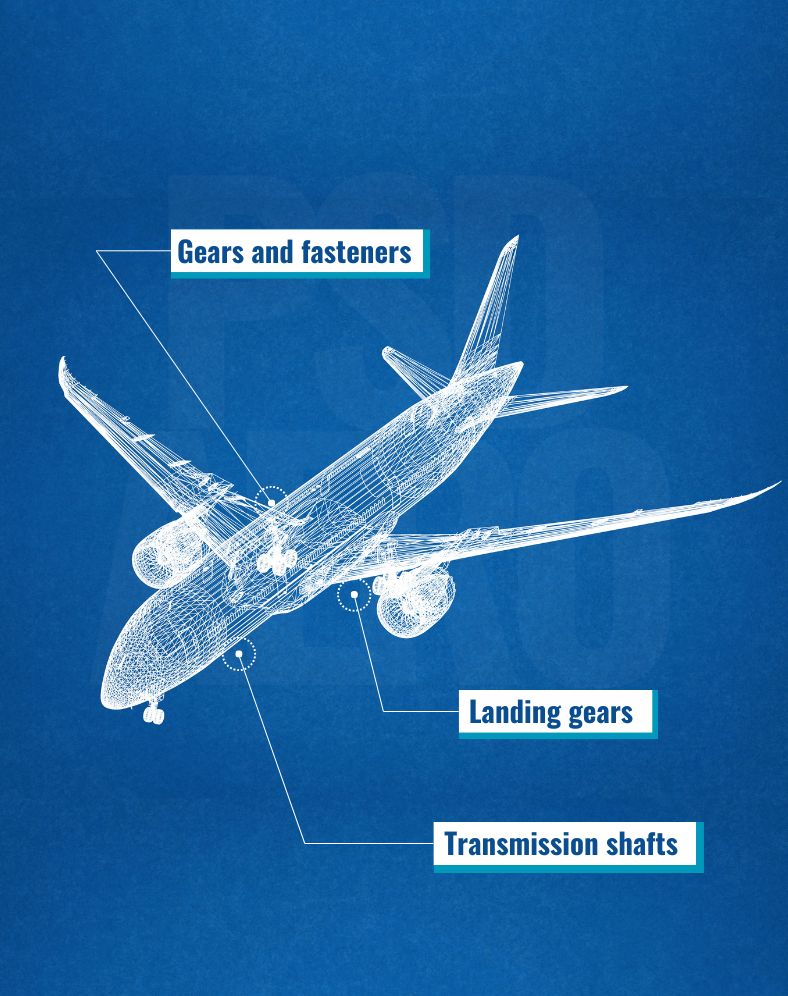

Landing gears

Designed to withstand the severe shocks of landings and takeoffs, landing gears require strong fatigue resistance, such as that provided by 300M steel. Long a competitor of 35NCD16, 300M is now preferred for these applications.

Drive shafts

Connecting engines to propellers or rotors, aircraft drive shafts demand exceptional torsion and fatigue resistance. 300M steel meets these criteria, ensuring efficient power transmission to helicopters and turboprop engines.

Gears and high-strength bolts

The high-strength 300M steel is widely used in critical applications. Its exceptional resistance to wear, high loads, and tensile stress makes it suitable for gears and fasteners in aircraft. Resistant to vibrations, temperature cycles, and high pressures, 300M steel ensures the reliability of propulsion systems and structural components.