Steel 32CDV13 - 1.8522 - 33CrMoV12 - FE-PL1504

The 32CDV13 is a high-performance low-alloy steel, suitable for nitriding, quenching, and tempering treatments. This grade is renowned for its longevity and its resistance to high thermal and mechanical stresses. It is ideal for manufacturing components in power transmission systems that experience high cyclic surface stresses. Similar to 16NCD13, these treatments provide it with remarkable surface hardness and ideal core ductility.

Available shapes :

Order 32CDV13 Online

Select the desired form, standard, or specification and place your order with one click. A member of our sales team will contact you promptly to finalize your order.

A high-performance steel for aerospace: the 32CDV13 grade

The 32CDV13 is a high-performance steel that has been historically recognized as such. Emerging in the second half of the 20th century, this grade has been the subject of numerous studies conducted by companies in various sectors - such as Safran, Airbus, Naval Group, and NTN-SNR - in France and internationally.

This alloy is widely used in mechanical power transmission systems, which are constantly subjected to intense and repeated stress. It is found in the main transmission gearboxes of helicopters, which require high load-bearing capacity, as well as in accessory drive systems of aircraft turbine engines, where bearings operate at high speed and under high temperatures. This steel therefore meets the strict requirements of the aerospace sector: it exhibits excellent resistance to temperature variations, fatigue, and tensile stress, as well as remarkable dimensional stability.

Before treatment, it offers good machinability and acceptable weldability, provided that pre- and post-heating parameters are respected. After treatment, the 32CDV13 forms an optimized structure. Its surface layer hardens, while a deeper diffusion layer forms, which is more ductile yet still harder than the original core, exhibiting a martensitic microstructure. Depending on the applied treatment, its surface hardness can reach 300 to 400 HB with good resilience, and up to 1000 Vickers after nitriding.

These characteristics make it an essential material for demanding aerospace and mechanical applications.

Chemical composition of 32CDV13

The variations in its chemical composition for aerospace.

| % | C Carbon | Cr Chromium | Mn Manganese | Mo Molybdenum | Ni Nickel | P Phosphorus | S Sulfur | Si Silicon | V Vanadium |

|---|---|---|---|---|---|---|---|---|---|

| Min. | 0.29 | 2.80 | 0.40 | 0.70 | <0.00 | <0.00 | <0.00 | 0.10 | 0.15 |

| Max. | 0.36 | 3.30 | 0.70 | 1.20 | 0.30 | 0.025 | 0.020 | 0.40 | 0.35 |

Related steel alloys

12NC12, FE-PL61

ROUND BAR

15CDV6, 15CrMoV6, 1.7734, 1.7736, AIR 9160

SQUARE BAR, RECTANGULAR BAR, ROUND BAR, WIRE, SHEET, ROUND TUBE

16NCD13, 1.6657, 14NiCrMo 13-4

ROUND BAR

25CD4S, 1.7218, 25CrMo4, FLE-PL1502

RECTANGULAR BAR, ROUND BAR, SHEET, SQUARE TUBE, ROUND TUBE

300M, A646, K44220

SQUARE BAR, ROUND BAR

30CD12, 1.8515, 30CrMo12, 31CrMo12, FE-PL1501

ROUND BAR

30CND8, 1.6580, 30CrNiMo8

ROUND BAR

30NCD16, 1.6747, 30NiCrMo16-6, FE-PL2107, 30Ni4CrMoA

SQUARE BAR, RECTANGULAR BAR, ROUND BAR

35CD4, 1.7220, 34CrMo4, 35CrMo4, FE-PL1503

ROUND BAR, ROUND TUBE

35NC6, 1.5815, 35NiCr6, FE-PL2102

SQUARE BAR, HEXAGONAL BAR, RECTANGULAR BAR, ROUND BAR, WIRE

35NCD16, 1.6773, 36NiCrMo16, FE-PL2108

SQUARE BAR, RECTANGULAR BAR, ROUND BAR

40CAD6-10

ROUND BAR

40CDV12, 40CrMoV12, FE-PL1507

PROFILE

40NCD7, 40NiCrMo7

ROUND BAR

42CD4

ROUND BAR

45SCD6

ROUND BAR

C75S

SHEET

DC04, Fe P04, St 14, ES

SHEET

E15CDV6

ROUND BAR, SHEET

E16NCD13

ROUND BAR

E32CDV13

RECTANGULAR BAR, ROUND BAR

E35NCD16

ROUND BAR

E40CDV12

ROUND BAR

E4330, 4330 Mod, A646 Grade 5

ROUND BAR

FER PUR

SHEET

GENRE STUB

ROUND BAR

S145F

SQUARE BAR, RECTANGULAR BAR

S145H

ROUND BAR

S534

SHEET

S97D

ROUND BAR

S98D

ROUND BAR

S99

ROUND BAR

X210CR12

ROUND BAR

X30Cr13, Z30C13

ROUND BAR

XC18S

ROUND BAR, SHEET, ROUND TUBE

XC38

ROUND BAR

Z230KDWVC11

ROUND BAR

Key properties

The most remarkable properties of this steel alloy

Ductility

≥10%

Tensile Strength

950-1400 MPa

Impact Toughness

≥600 kJ/m²

Yield Strength

≥800 MPa

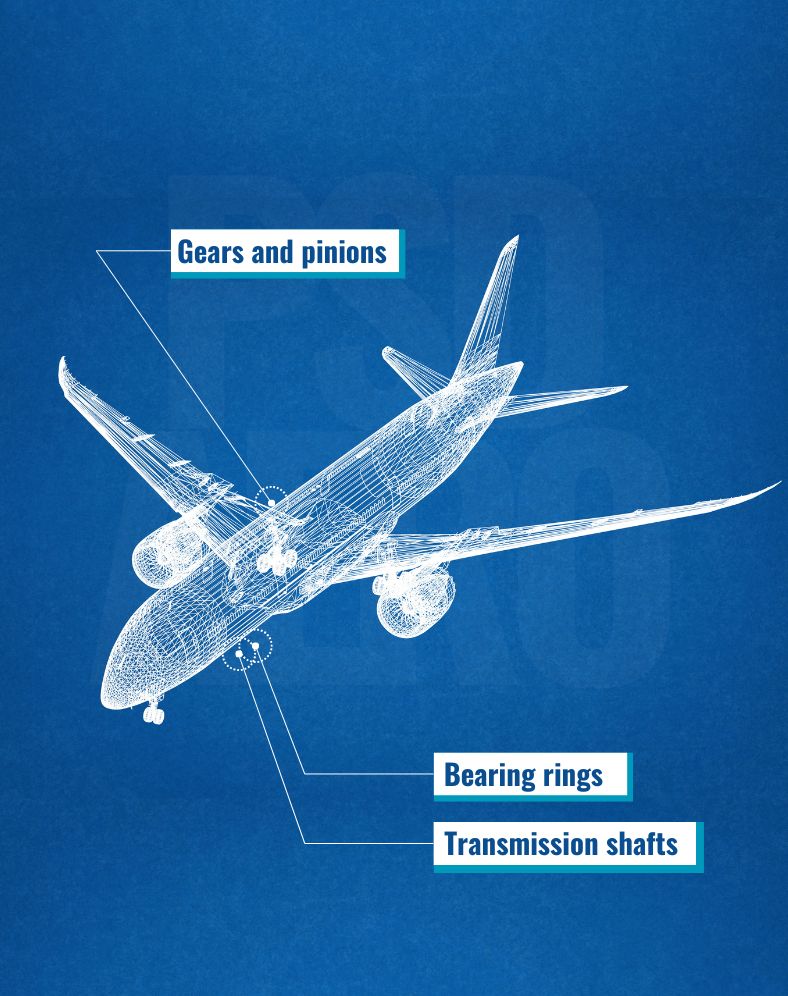

How 32CDV13 is used in aerospace

The practical applications of this steel in aircraft construction.

Bearing rings

Bearings made of 32CDV13 can operate at temperatures of up to 400°C, providing stability and durability.

Transmission shafts

Transmission shafts in gearboxes benefit from the robustness and durability offered by 32CDV13.

Gears and pinions

The fatigue and tensile strength of this alloy make it a commonly used material for gears and pinions.