Steel 30CD12 - 1.8515 - 30CrMo12 - 31CrMo12 - FE-PL1501

The 30CD12 steel (or 31CrMo12) is an alloy designed for nitriding. After treatment, it features a hard surface, reaching up to 800 HV, while maintaining good toughness at its core. These properties make it wear-resistant and ensure the durability of the parts in which it is used. Its chemical composition (chromium, carbon, and nickel) along with the various possible heat treatments (quenching, tempering) provide remarkable mechanical properties and contribute to its popularity. In addition to its wear resistance, 30CD12 boasts excellent tensile strength, which is why it is used for manufacturing gears and shafts, especially in the aerospace industry, where components are subjected to high stress.

Available shapes :

Order 30CD12 Online

Select the desired form, standard, or specification and place your order with one click. A member of our sales team will contact you promptly to finalize your order.

Chemical composition of 30CD12

The variations in its chemical composition for aerospace.

| % | C Carbon | Cr Chromium | Mn Manganese | Mo Molybdenum | Ni Nickel | P Phosphorus | S Sulfur | Si Silicon |

|---|---|---|---|---|---|---|---|---|

| Min. | 0.28 | 2.80 | 0.40 | 0.30 | <0.00 | <0.00 | <0.00 | 0.10 |

| Max. | 0.35 | 3.30 | 0.70 | 0.50 | 0.30 | 0.025 | 0.020 | 0.40 |

Related steel alloys

12NC12, FE-PL61

ROUND BAR

15CDV6, 15CrMoV6, 1.7734, 1.7736, AIR 9160

SQUARE BAR, RECTANGULAR BAR, ROUND BAR, WIRE, SHEET, ROUND TUBE

16NCD13, 1.6657, 14NiCrMo 13-4

ROUND BAR

25CD4S, 1.7218, 25CrMo4, FLE-PL1502

RECTANGULAR BAR, ROUND BAR, SHEET, SQUARE TUBE, ROUND TUBE

300M, A646, K44220

SQUARE BAR, ROUND BAR

30CND8, 1.6580, 30CrNiMo8

ROUND BAR

30NCD16, 1.6747, 30NiCrMo16-6, FE-PL2107, 30Ni4CrMoA

SQUARE BAR, RECTANGULAR BAR, ROUND BAR

32CDV13, 1.8522, 33CrMoV12, FE-PL1504

ROUND BAR

35CD4, 1.7220, 34CrMo4, 35CrMo4, FE-PL1503

ROUND BAR, ROUND TUBE

35NC6, 1.5815, 35NiCr6, FE-PL2102

SQUARE BAR, HEXAGONAL BAR, RECTANGULAR BAR, ROUND BAR, WIRE

35NCD16, 1.6773, 36NiCrMo16, FE-PL2108

SQUARE BAR, RECTANGULAR BAR, ROUND BAR

40CAD6-10

ROUND BAR

40CDV12, 40CrMoV12, FE-PL1507

PROFILE

40NCD7, 40NiCrMo7

ROUND BAR

42CD4

ROUND BAR

45SCD6

ROUND BAR

C75S

SHEET

DC04, Fe P04, St 14, ES

SHEET

E15CDV6

ROUND BAR, SHEET

E16NCD13

ROUND BAR

E32CDV13

RECTANGULAR BAR, ROUND BAR

E35NCD16

ROUND BAR

E40CDV12

ROUND BAR

E4330, 4330 Mod, A646 Grade 5

ROUND BAR

FER PUR

SHEET

GENRE STUB

ROUND BAR

S145F

SQUARE BAR, RECTANGULAR BAR

S145H

ROUND BAR

S534

SHEET

S97D

ROUND BAR

S98D

ROUND BAR

S99

ROUND BAR

X210CR12

ROUND BAR

X30Cr13, Z30C13

ROUND BAR

XC18S

ROUND BAR, SHEET, ROUND TUBE

XC38

ROUND BAR

Z230KDWVC11

ROUND BAR

Key properties

The most remarkable properties of this steel alloy

Ductility

≥11%

Tensile Strength

930-1270 MPa

Impact Toughness

≥800 kJ/m²

Yield Strength

≥780 MPa

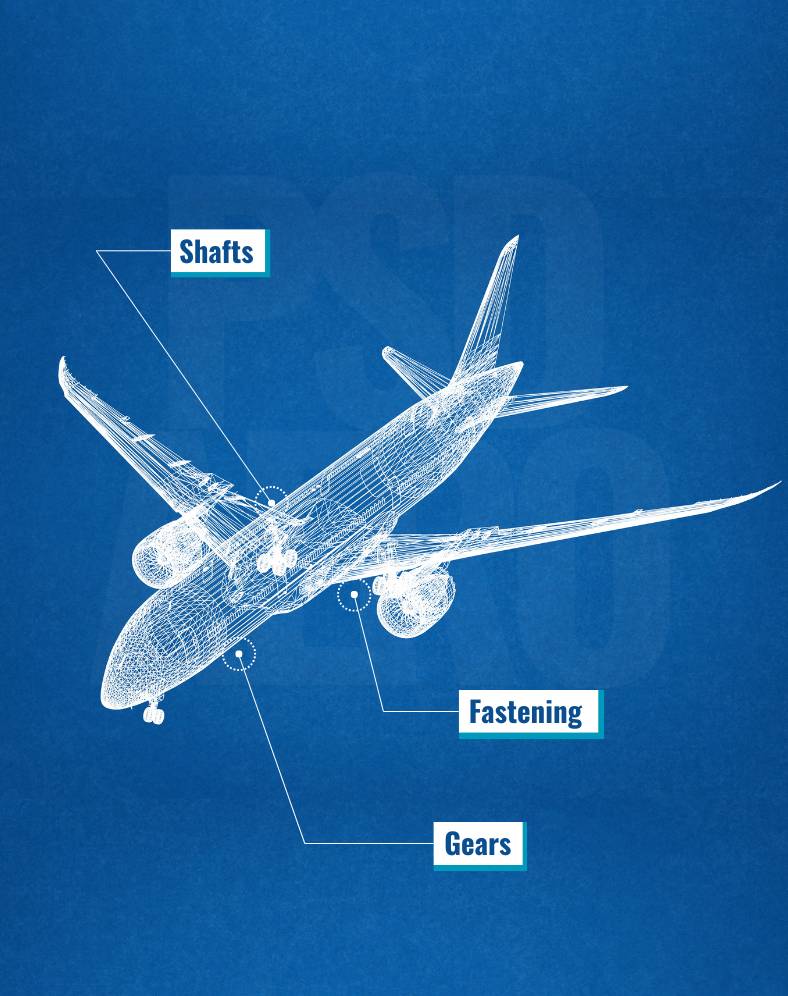

How 30CD12 is used in aerospace

The practical applications of this steel in aircraft construction.

Shafts

Used in components such as transmission and turbine shafts, 30CD12 steel offers excellent resistance to torsion and low-cycle fatigue.

Fasteners

Steel fasteners, such as retaining rings, provide solid holding power for parts exposed to repeated shocks and vibrations. The wear resistance and dimensional stability of 30CD12 after heat treatment make it a suitable alloy to ensure durable fastenings.

Gears

Gears made from 30CD12 benefit from a hard, wear-resistant surface. Subjected to heavy loads and fatigue cycles (due to variations in operating speed, for example), these parts enjoy reduced maintenance costs and increased lifespan thanks to this alloy.