Steel 35NCD16

1.6773 - 36NiCrMo16 - FE-PL2108

35NCD16 is a high-strength, low-alloy steel known for its excellent mechanical properties: high tensile strength, good toughness, and excellent resistance to wear and fatigue. Its ability to maintain mechanical integrity under high stress makes it an ideal choice for applications requiring both strength and durability.

Available shapes :

Order 35NCD16 Online

Select the desired form, standard, or specification and place your order with one click. A member of our sales team will contact you promptly to finalize your order.

A famous steel, known for its resistance

35NCD16, or 1.6747, is a high-strength low-alloy steel renowned for its exceptional toughness and dimensional stability. This nickel-chromium-molybdenum steel is utilized in aerospace, automotive, and industrial machinery due to its robust mechanical properties, such as tensile strength (1050-1380 MPa) and yield strength of at least 900 MPa. Its composition, which includes a high percentage of nickel and chromium, contributes to its remarkable strength. Heat treatments such as quenching and tempering further enhance its performance, making it ideal for high-stress components like landing gear, gears, and heavy-duty shafts.

These mechanical properties and more make 35NCD16 an optimal choice for applications requiring high performance and reliability in aerospace. It was even used for certain parts of the famous Concorde!

Chemical composition of 35NCD16

The variations in its chemical composition for aerospace.

| % | C Carbon | Cr Chromium | Mn Manganese | Mo Molybdenum | Ni Nickel | P Phosphorus | S Sulfur | Si Silicon |

|---|---|---|---|---|---|---|---|---|

| Min. | 0.30 | 1.60 | 0.30 | 0.25 | 3.50 | <0.00 | <0.00 | 0.15 |

| Max. | 0.40 | 2.00 | 0.60 | 0.60 | 4.20 | 0.03 | 0.02 | 0.40 |

Related steel alloys

12NC12, FE-PL61

ROUND BAR

15CDV6, 15CrMoV6, 1.7734, 1.7736, AIR 9160

SQUARE BAR, RECTANGULAR BAR, ROUND BAR, WIRE, SHEET, ROUND TUBE

16NCD13, 15NiCrM013

ROUND BAR

25CD4S, 1.7218, 25CrMo4, FLE-PL1502

RECTANGULAR BAR, ROUND BAR, SHEET, SQUARE TUBE, ROUND TUBE

300M, A646, K44220

SQUARE BAR, ROUND BAR

30CD12, 32CrMo12

ROUND BAR

30CND8

ROUND BAR

30NCD16, 1.6747, 30NiCrMo16-6, FE-PL2107, 30Ni4CrMoA

SQUARE BAR, RECTANGULAR BAR, ROUND BAR

32CDV13, 33CrMoV12

ROUND BAR

35CD4, 36CrMo4

ROUND BAR, ROUND TUBE

35NC6, 35NiCr6

SQUARE BAR, HEXAGONAL BAR, RECTANGULAR BAR, ROUND BAR, WIRE

40CAD6-10

ROUND BAR

40CDV12

PROFILE

40NCD7, 40NiCrMo7

ROUND BAR

42CD4

ROUND BAR

45SCD6

ROUND BAR

C75S

SHEET

DC04, Fe P04, St 14, ES

SHEET

E15CDV6

ROUND BAR, SHEET

E16NCD13

ROUND BAR

E32CDV13

RECTANGULAR BAR, ROUND BAR

E35NCD16

ROUND BAR

E40CDV12

ROUND BAR

E4330, 4330 Mod, A646 Grade 5

ROUND BAR

FER PUR

SHEET

GENRE STUB

ROUND BAR

S145F

SQUARE BAR, RECTANGULAR BAR

S145H

ROUND BAR

S534

SHEET

S97D

ROUND BAR

S98D

ROUND BAR

S99

ROUND BAR

X210CR12

ROUND BAR

X30Cr13, Z30C13

ROUND BAR

XC18S

ROUND BAR, SHEET, ROUND TUBE

XC38

ROUND BAR

Z230KDWVC11

ROUND BAR

Key properties

The most remarkable properties of this steel alloy

Tensile Strength

1080-2010 MPa

Impact Toughness

≥300 kJ/m²

Yield Strength

≥880 MPa

Brinell Hardness

≥295

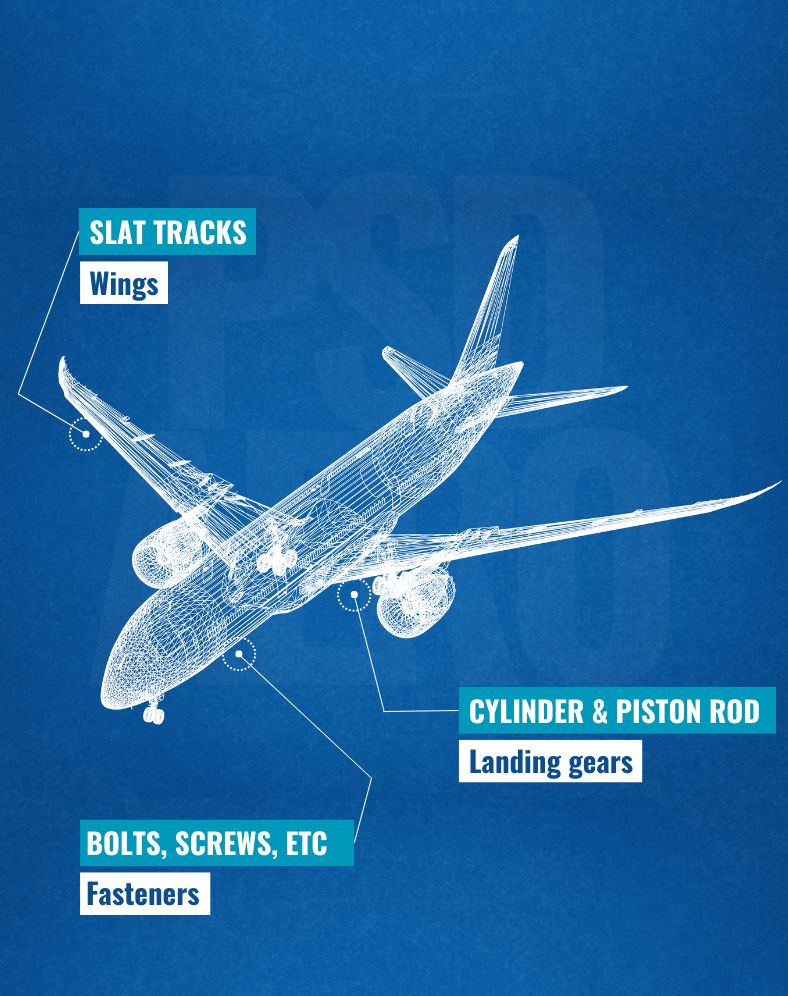

How 35NCD16 is used in aerospace

The practical applications of this steel in aircraft construction.

Wings

The 35NCD16 steel alloy is used in the wings, more specifically in the leading edge slat tracks. These allow the slats to extend and retract to facilitate takeoff and landing phases.

Landing Gear

Particularly suited for this use, the 35NCD16 finds its place in the strut and its sliding rod. These two parts work together to absorb shocks during landing. It was even chosen for the Concorde’s landing gear!

Fasteners

Such small elements as screws and bolts play a crucial part in the safety of airplanes. The excellent properties of the 35NCD16 meet this need for resistance to deformations : it is widely used in aerospace structures.

Optimizing the use of 35NCD16 : treatments, regulations, and options.

Applications of

35NCD16 steel

How it is used in various industries.