Steel 15CDV6 - 15CrMoV6 - 1.7734 - 1.7736 - AIR 9160

The 15CDV6 is a high-strength alloy steel often used in the aerospace industry. It combines chromium, vanadium, and other elements to provide excellent mechanical strength and good toughness. Picture a steel that is robust yet flexible, capable of withstanding challenging conditions such as temperature changes or high pressures.

Available shapes :

Order 15CDV6 Online

Select the desired form, standard, or specification and place your order with one click. A member of our sales team will contact you promptly to finalize your order.

Highly Regarded Steel in Aerospace

15CDV6 (15CrMoV6 - 1.7734 - 1.7736 - AIR 9160 15CDV6) is a highly regarded steel in the aerospace industry. Its popularity is based on a set of properties that meet the strict standards of this demanding industry. Its high tensile and compressive mechanical strength qualifies it as a material of choice for structural components that endure high stresses. This robustness is not just a mechanical attribute but also a guarantee of safety, as it is accompanied by good toughness. In fact, 15CDV6's ability to resist fracture or cracking under various load conditions makes it a reliable option in an industry where safety cannot be compromised.

This grade also has excellent machinability. Whether for cutting, forming, or welding, 15CDV6 readily lends itself to various processing methods, thereby reducing production costs. This ease of handling goes hand in hand with excellent thermal stability. This last point is crucial in aerospace, where components are subjected to extreme temperature ranges, from very cold to very hot, without compromising their performance.

Another advantage of 15CDV6 is its low weight. For similar mechanical performance, it offers a more favorable strength-to-weight ratio than many other steels. In the field of aerospace, where every gram matters, this property is highly appreciated. Moreover, its chemical composition makes it compatible with other metals and composite materials frequently used in the aerospace industry. This compatibility facilitates its integration into complex systems, making it a preferred choice for engineers and aircraft designers.

In summary, 15CDV6 is a multifunctional material that excels in various areas such as mechanical strength, toughness, machinability, thermal stability, and lightweight properties, while also being compatible with a wide range of materials used in aerospace.

Chemical composition of 15CDV6

The variations in its chemical composition for aerospace.

| % | C Carbon | Si Silicon | Mn Manganese | P Phosphorus | S Sulfur | Cr Chromium | Mo Molybdenum | V Vanadium |

|---|---|---|---|---|---|---|---|---|

| Min. | 0.12 | >0 | 0.8 | >0 | >0 | 0.25 | 0.8 | 0.2 |

| Max. | 0.18 | 0.2 | 1 | 0.025 | 0.015 | 1.5 | 1 | 0.3 |

Related steel alloys

12NC12, FE-PL61

ROUND BAR

16NCD13, 1.6657, 14NiCrMo 13-4

ROUND BAR

25CD4S, 1.7218, 25CrMo4, FLE-PL1502

RECTANGULAR BAR, ROUND BAR, SHEET, SQUARE TUBE, ROUND TUBE

300M, A646, K44220

SQUARE BAR, ROUND BAR

30CD12, 1.8515, 30CrMo12, 31CrMo12, FE-PL1501

ROUND BAR

30CND8, 1.6580, 30CrNiMo8

ROUND BAR

30NCD16, 1.6747, 30NiCrMo16-6, FE-PL2107, 30Ni4CrMoA

SQUARE BAR, RECTANGULAR BAR, ROUND BAR

32CDV13, 1.8522, 33CrMoV12, FE-PL1504

ROUND BAR

35CD4, 1.7220, 34CrMo4, 35CrMo4, FE-PL1503

ROUND BAR, ROUND TUBE

35NC6, 1.5815, 35NiCr6, FE-PL2102

SQUARE BAR, HEXAGONAL BAR, RECTANGULAR BAR, ROUND BAR, WIRE

35NCD16, 1.6773, 36NiCrMo16, FE-PL2108

SQUARE BAR, RECTANGULAR BAR, ROUND BAR

40CAD6-10

ROUND BAR

40CDV12, 40CrMoV12, FE-PL1507

PROFILE

40NCD7, 40NiCrMo7

ROUND BAR

42CD4

ROUND BAR

45SCD6

ROUND BAR

C75S

SHEET

DC04, Fe P04, St 14, ES

SHEET

E15CDV6

ROUND BAR, SHEET

E16NCD13

ROUND BAR

E32CDV13

RECTANGULAR BAR, ROUND BAR

E35NCD16

ROUND BAR

E40CDV12

ROUND BAR

E4330, 4330 Mod, A646 Grade 5

ROUND BAR

FER PUR

SHEET

GENRE STUB

ROUND BAR

S145F

SQUARE BAR, RECTANGULAR BAR

S145H

ROUND BAR

S534

SHEET

S97D

ROUND BAR

S98D

ROUND BAR

S99

ROUND BAR

X210CR12

ROUND BAR

X30Cr13, Z30C13

ROUND BAR

XC18S

ROUND BAR, SHEET, ROUND TUBE

XC38

ROUND BAR

Z230KDWVC11

ROUND BAR

Key properties

The most remarkable properties of this steel alloy

Ductility

≥10%

Tensile Strength

980-1280 MPa

Yield Strength

≥780 MPa

Brinell Hardness

291-380

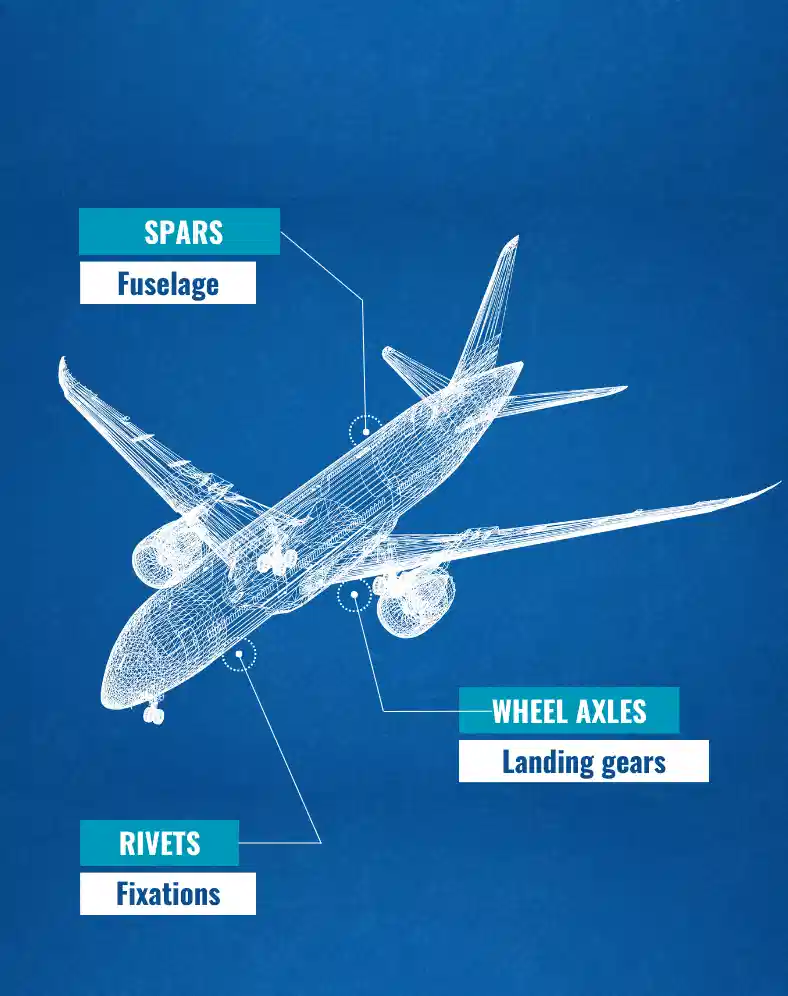

How 15CDV6 is used in aerospace

The practical applications of this steel in aircraft construction.

Fuselage

The 15CDV6 grade is often used for aircraft chassis and fuselage structures. In addition to stringers (longitudinal beams that provide structural support for the fuselage), this steel is applied to the ribs and frame of the fuselage.

Landing Gear

The high resistance to wear and fatigue of 15CDV6 makes it ideal for landing gear components, which are subject to high stress: its struts, wheel axles, or even the relay connecting rod.

Fasteners

15CDV6 is also used for bolts, screws, and other fasteners like rivets. Its high mechanical strength and corrosion resistance make it a steel of choice to ensure the reliability of these elements.