Stainless steel 21-6-9 - AMS 5561 - Nitronic 40 - S21900 - X2CrMnNi21-6-9 - Z4CMN 21-9-6

21-6-9, also known as AMS 5561, UNS S21900, or Nitronic 40, is an austenitic stainless steel alloy strengthened with nitrogen. This enhancement provides superior corrosion resistance compared to standard 300-series steels, excellent toughness (a characteristic of austenitic alloys), and high mechanical strength. Its ability to withstand cryogenic temperatures makes it highly sought after for aerospace applications.

Available shapes :

Order 21-09-06 Online

Select the desired form, standard, or specification and place your order with one click. A member of our sales team will contact you promptly to finalize your order.

General Introduction to 21-6-9

Thanks to its high chromium content, this steel resists oxidation and corrosion even under aggressive conditions such as intergranular corrosion. Its reinforcement with manganese and nitrogen increases the strength and stability of the austenite and gives it excellent toughness, which it retains down to temperatures close to those of liquid helium (-269 °C or -516 °F).

The 21-6-9 alloy does not respond to heat treatments for hardening by quenching, tempering, or aging, unlike martensitic steels. On one hand, it does not contain enough aluminum, titanium, or copper to allow for age hardening. On the other, its austenite is too stable at low temperatures for quenching or tempering to be effective. However, cold working to increase hardness is possible—or hot working to improve ductility—without degrading the material.

Hot Working, Cold Working

21-6-9 stainless steel should be hot worked in a temperature range between 927 °C and 1204 °C (1700–2200 °F). Maintaining a controlled temperature is essential to avoid damaging the material’s microstructure.

- Heat the alloy evenly to ensure uniform deformation.

- Cool rapidly to room temperature (water or air) to preserve mechanical properties.

Serve while it's hot.

Cold working includes rolling, drawing, and stamping at room temperature. Due to its high work hardening rate, 21-6-9 requires higher forming forces than other austenitic stainless steels (such as 302, 304, and 316). An intermediate anneal is necessary to reduce hardness and facilitate further cold working. This process (cold work → anneal → further cold work) significantly increases its yield strength.

Mechanical and Chemical Properties

When hardened (work hardened), 21-6-9 has a yield strength of at least 827 MPa, ensuring durability under heavy loads. Its tensile strength can reach 1117 MPa. Its elongation capability is at least 35 % in the annealed state, and it maintains at least 20 % elongation when hardened.

This alloy remains non-magnetic even after severe cold working, an important characteristic of Nitronic grades (unlike 301/304 steels, which can become slightly magnetic after work hardening due to martensite formation). The austenite in 21-6-9 is very stable.

Machinability, Formability

Because of its high work hardening rate, 21-6-9 is more difficult to machine than most austenitic stainless steels. Similar to type 316, it is recommended to use slow cutting speeds, positive feeds, and ample cutting fluids.

It offers good formability and handling in the annealed condition. However, its high yield strength and work hardening rate require greater forces during forming than other steels like 304L. Techniques such as bending, drawing, and stretching can be applied, but an intermediate anneal may be necessary to prevent cracking and ensure uniform deformation.

Weldability

21-6-9 is considered to have good weldability. Several welding methods can be successfully applied:

- TIG welding produces precise welds. An inert gas such as argon or helium protects the weld zone.

- MIG welding offers high deposition rates.

- SMAW (shielded metal arc welding) is also suitable. A complete post-weld anneal is recommended to reduce residual stresses and restore corrosion resistance.

Oxy-acetylene welding should be avoided, as it risks carbon buildup that would compromise the material’s properties.

Industrial applications

In addition to the aerospace industry, the 21-6-9 alloy is also used for:

- Cryogenic applications: tanks, piping, valves, and fittings for cryogenic storage and transport vessels (LNG, liquid nitrogen, liquid helium)

- Chemical and petrochemical processing: pressure vessels and reactors

- Marine applications: propeller shafts for boats and ships

- Automotive (high-performance / specialized)

- Nuclear

Chemical composition of 21-09-06

The variations in its chemical composition for aerospace.

| % | C Carbon | Cr Chromium | Cu Copper | Mn Manganese | Mo Molybdenum | N Nitrogen | Ni Nickel | P Phosphorus | S Sulfur | Si Silicon |

|---|---|---|---|---|---|---|---|---|---|---|

| Min. | <0.00 | 19.00 | <0.00 | 8.00 | <0.00 | 0.15 | 5.50 | <0.00 | <0.00 | <0.00 |

| Max. | 0.04 | 21.50 | 0.75 | 10.00 | 0.75 | 0.40 | 7.50 | 0.03 | 0.03 | 1.00 |

Related stainless steel alloys

15-5PH, 1.4545, X5CrNiCu15-5, EZ5CNU15.15

RECTANGULAR BAR, ROUND BAR, PROFILE, SHEET

17-4PH, 1.4548, UNS S17400, AMS 5643, AMS 5622, S17400

SQUARE BAR, RECTANGULAR BAR, ROUND BAR, SHEET

17-7PH, S17700, 1.4568, AISI 631, X7CrNiAl17-7

SHEET

AISI 301, Z12CN18-07, X12CrNi17-7, X10CrNi18-8

MOTHER COIL, COIL, SHEET

AISI 302, Z12CN18-09

SHEET

AISI 347, X6CrNiNb18-10, Z6CNNb18-11

RECTANGULAR BAR, ROUND BAR, SHEET, ROUND TUBE

AISI 431, X17CrNi16-2, Z15CN16-02, FE PM42, 1.4057, APX

SQUARE BAR, RECTANGULAR BAR, ROUND BAR, SHEET

AISI 446

ROUND BAR

CALE PELABLE

SHEET

CUSTOM 465, MLX17, X1CrNiMoAlTi12-11

ROUND BAR

EZ100CD17

ROUND BAR

EZ12CNDV12

ROUND BAR

EZ15CN17-03

ROUND BAR

EZ1CNDAT12-09, MARVALX12, X1CrNiMoAlTi12-9

ROUND BAR

EZ2NKD18-8-5, MARAGING 250, X2NiCoMo18-8-5

RECTANGULAR BAR

EZ3NCT25, X3NiCrTi25

ROUND BAR, COIL, SHEET (THICKNESS > 6MM)

EZ6CND16-05-01

SQUARE BAR

EZ6NCT25, A286, X6NiCrTi25

SQUARE BAR, RECTANGULAR BAR, ROUND BAR, COIL, WIRE, SHEET

EZ8CND17-04

ROUND BAR

GD223, X50NiMnCr12, Z50NMC12

ROUND BAR

PH13-8Mo, X3CrNiMoAl13-08-02, Z3CND13-08

RECTANGULAR BAR, ROUND BAR

S130

ROUND BAR

S143

ROUND BAR

S143D

ROUND BAR

S144

ROUND BAR

S145

ROUND BAR

X12C13, X12Cr13, AISI 410, 1.4006, Z10C13

ROUND BAR, SHEET

X30Cr13, Z30C13

ROUND BAR

X6Cr17

ROUND BAR

X750

SHEET

Z100CD17

ROUND BAR

Z12CN13

SHEET

Z12CNDV12, JETHETE M152, X12CrNiMoV12

ROUND BAR, SHEET

Z25CNWS22

ROUND BAR

Z2CN18-10, AISI 304L, X1CrNi18-10

RECTANGULAR BAR, ROUND BAR, COIL, WIRE, PROFILE, SHEET, PERFORATED SHEET, PVC SHEET, ROUND TUBE

Z6CND16-05-01, APX4, Z8CND17-04, X4CrNiMo16-5-1

ROUND BAR, SHEET

Z6CNT18-10, AISI 321, X6CrNiTi18-10, X6CNT18-10

SQUARE BAR, RECTANGULAR BAR, ROUND BAR, COIL, SHEET, ROUND TUBE

Key properties

The most remarkable properties of this stainless steel alloy

Reduction of Area Z

73.638–79.167 %

Tensile Strength

690–1117 MPa

Impact Toughness

115.2–325.3 J

Yield Strength

≥ 386.4 MPa

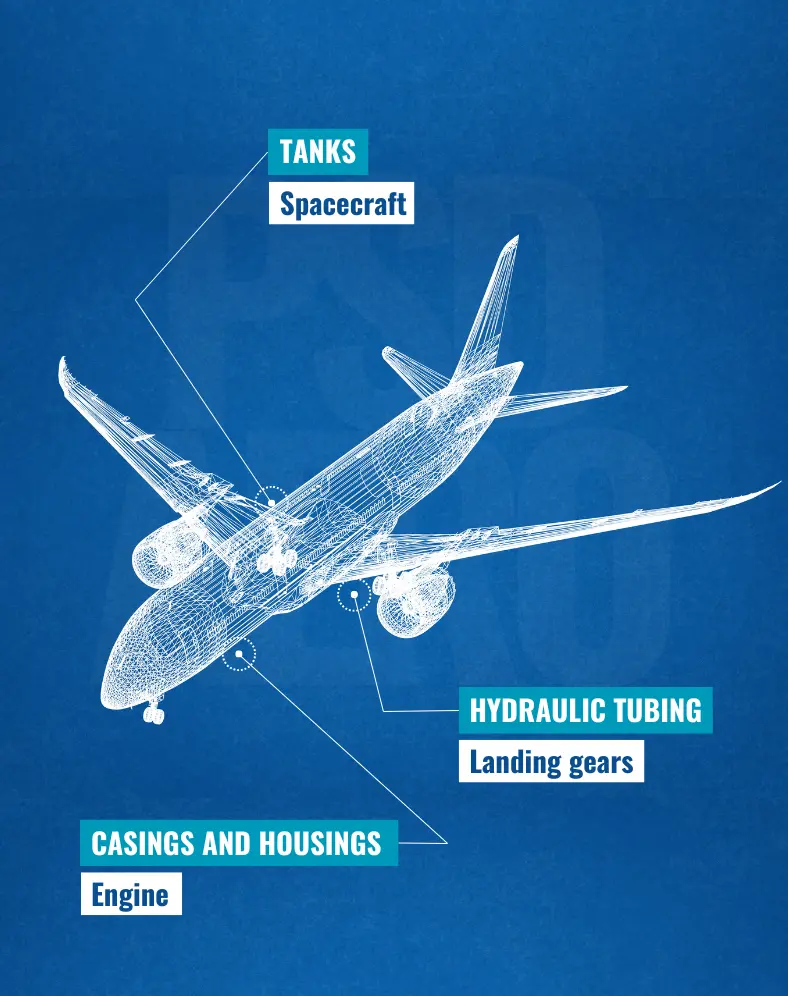

How 21-09-06 is used in aerospace

The practical applications of this stainless steel in aircraft construction.

Cryogenic tanks and lines

A key application area for 21-6-9, used in liquid-fueled rockets.

Casings and housings

21-6-9 is used in compressor casings or engine exhaust systems for its good fatigue and corrosion resistance, as well as its formability.

Hydraulic tubing

Another major application of 21-6-9 is in the aircraft's hydraulic system, including fittings, for example, and components of the landing gear.