Stainless steel 17-4PH - 1.4548 - UNS S17400 - AMS 5643 - AMS 5622 - S17400

17-4PH stainless steel combines high mechanical strength, durability at elevated temperatures, and versatile usability. Highly valued in demanding sectors such as aerospace, medical, and energy industries, this martensitic precipitation-hardening alloy is well-suited for components subject to significant mechanical stresses requiring corrosion resistance. Discover everything you need to know about the properties, heat treatments, machinability, and key industrial applications of 17-4PH stainless steel.

Available shapes :

Order 17-4PH Online

Select the desired form, standard, or specification and place your order with one click. A member of our sales team will contact you promptly to finalize your order.

Everything You Need to Know About 17-4PH Stainless Steel

Like all stainless steels, the chromium present in 17-4PH allows the formation of a passivation layer on the metal's surface, granting it resistance to oxidation and rust. This martensitic PH ("Precipitation Hardening") steel alloy undergoes heat treatment through solution treatment followed by aging and offers good corrosion resistance and high-temperature performance up to 316°C. It hardens during aging, unlike QT-type (Quenched and Tempered) martensitic steel, which reaches its peak hardness after quenching and is softened by tempering.

Heat Treatments

The mechanical properties of 17-4 PH are achieved through a two-step heat treatment. Solution treatment (Condition A) involves heating the alloy to approximately 1040°C, then quenching it to obtain a relatively soft martensitic structure. Aging, performed at lower temperatures (between 480°C and 620°C) for varying durations, causes the precipitation of fine particles that harden the material.

Different aging conditions (H900, H1025, H1075, H1150, etc.) each offer different trade-offs between strength, ductility, and corrosion resistance. For example, the H900 condition provides maximum strength and hardness, while the H1150 condition prioritizes corrosion resistance and ductility.

Mechanical and Chemical Properties

After precipitation hardening, 17-4PH steel can achieve a tensile strength of up to 1552 MPa, a yield strength exceeding 1236 MPa, and a hardness of 444 (HB).

While it has good corrosion resistance in many environments for a martensitic stainless steel, 17-4PH has certain limitations. It is generally less resistant than austenitic stainless steels such as 304 or 316, but close to them in chloride-containing environments (such as seawater). The choice of heat treatment condition significantly influences corrosion resistance, with lower hardness conditions generally offering better resistance but at the expense of mechanical properties.

Machinability and Weldability

The 17-4PH grade has good machinability, influenced by its heat treatment condition. In Condition A, it is comparable to that of some austenitic stainless steels, exhibiting some adhesion to cutting tools.

After aging, its increased hardness requires more robust tools, reduced cutting speeds, and effective cooling.

Finally, this grade can be welded using most processes. Welding is preferably performed before aging to avoid weakening the heat-affected zone.

It can also be forged through hammering, pressing, rolling, extrusion, or upsetting to produce a wrought structure. For maximum hardness, a re-solution treatment should be considered.

Industrial Applications

Thanks to its mechanical properties and corrosion resistance, 17-4PH steel is commonly used in:

- The aerospace industry

- The medical and surgical industry

- The chemical, oil, and gas industry. Tooling and prototyping (pump wheels, pipes, and valves), gas turbine components.

- The automotive industry

- Defense and firearms, etc.

Chemical composition of 17-4PH

The variations in its chemical composition for aerospace.

| % | Al Aluminium | C Carbon | Cr Chromium | Cu Copper | Mn Manganese | N Nitrogen | Nb Niobium | Ni Nickel | P Phosphorus | S Sulfur | Si Silicon | Sn Tin |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min. | <0.00 | <0.00 | 15.50 | 2.80 | <0.00 | <0.00 | 0.15 | 3.60 | <0.00 | <0.00 | 0.50 | <0.00 |

| Max. | 0.05 | 0.06 | 16.70 | 3.50 | 0.70 | 0.05 | 0.40 | 4.60 | 0.025 | 0.025 | 1.00 | 0.02 |

Related stainless steel alloys

15-5PH, 1.4545, X5CrNiCu15-5, EZ5CNU15.15

RECTANGULAR BAR, ROUND BAR, PROFILE, SHEET

17-7PH, S17700, 1.4568, AISI 631, X7CrNiAl17-7

SHEET

21-09-06, AMS 5561, Nitronic 40, S21900, X2CrMnNi21-6-9, Z4CMN 21-9-6

ROUND TUBE

AISI 301, Z12CN18-07, X12CrNi17-7, X10CrNi18-8

MOTHER COIL, COIL, SHEET

AISI 302, Z12CN18-09

SHEET

AISI 347, X6CrNiNb18-10, Z6CNNb18-11

RECTANGULAR BAR, ROUND BAR, SHEET, ROUND TUBE

AISI 431, X17CrNi16-2, Z15CN16-02, FE PM42, 1.4057, APX

SQUARE BAR, RECTANGULAR BAR, ROUND BAR, SHEET

AISI 446

ROUND BAR

CALE PELABLE

SHEET

CUSTOM 465, MLX17, X1CrNiMoAlTi12-11

ROUND BAR

EZ100CD17

ROUND BAR

EZ12CNDV12

ROUND BAR

EZ15CN17-03

ROUND BAR

EZ1CNDAT12-09, MARVALX12, X1CrNiMoAlTi12-9

ROUND BAR

EZ2NKD18-8-5, MARAGING 250, X2NiCoMo18-8-5

RECTANGULAR BAR

EZ3NCT25, X3NiCrTi25

ROUND BAR, COIL, SHEET (THICKNESS > 6MM)

EZ6CND16-05-01

SQUARE BAR

EZ6NCT25, A286, X6NiCrTi25

SQUARE BAR, RECTANGULAR BAR, ROUND BAR, COIL, WIRE, SHEET

EZ8CND17-04

ROUND BAR

GD223, X50NiMnCr12, Z50NMC12

ROUND BAR

PH13-8Mo, X3CrNiMoAl13-08-02, Z3CND13-08

RECTANGULAR BAR, ROUND BAR

S130

ROUND BAR

S143

ROUND BAR

S143D

ROUND BAR

S144

ROUND BAR

S145

ROUND BAR

X12C13, X12Cr13, AISI 410, 1.4006, Z10C13

ROUND BAR, SHEET

X30Cr13, Z30C13

ROUND BAR

X6Cr17

ROUND BAR

X750

SHEET

Z100CD17

ROUND BAR

Z12CN13

SHEET

Z12CNDV12, JETHETE M152, X12CrNiMoV12

ROUND BAR, SHEET

Z25CNWS22

ROUND BAR

Z2CN18-10, AISI 304L, X1CrNi18-10

RECTANGULAR BAR, ROUND BAR, COIL, WIRE, PROFILE, SHEET, PERFORATED SHEET, PVC SHEET, ROUND TUBE

Z6CND16-05-01, APX4, Z8CND17-04, X4CrNiMo16-5-1

ROUND BAR, SHEET

Z6CNT18-10, AISI 321, X6CrNiTi18-10, X6CNT18-10

SQUARE BAR, RECTANGULAR BAR, ROUND BAR, COIL, SHEET, ROUND TUBE

Key properties

The most remarkable properties of this stainless steel alloy

Tensile Strength

861.8–1552 MPa

Impact Toughness

≥ 25 J

Yield Strength

689.5–1236.6 MPa

Brinell Hardness

269–444 HB

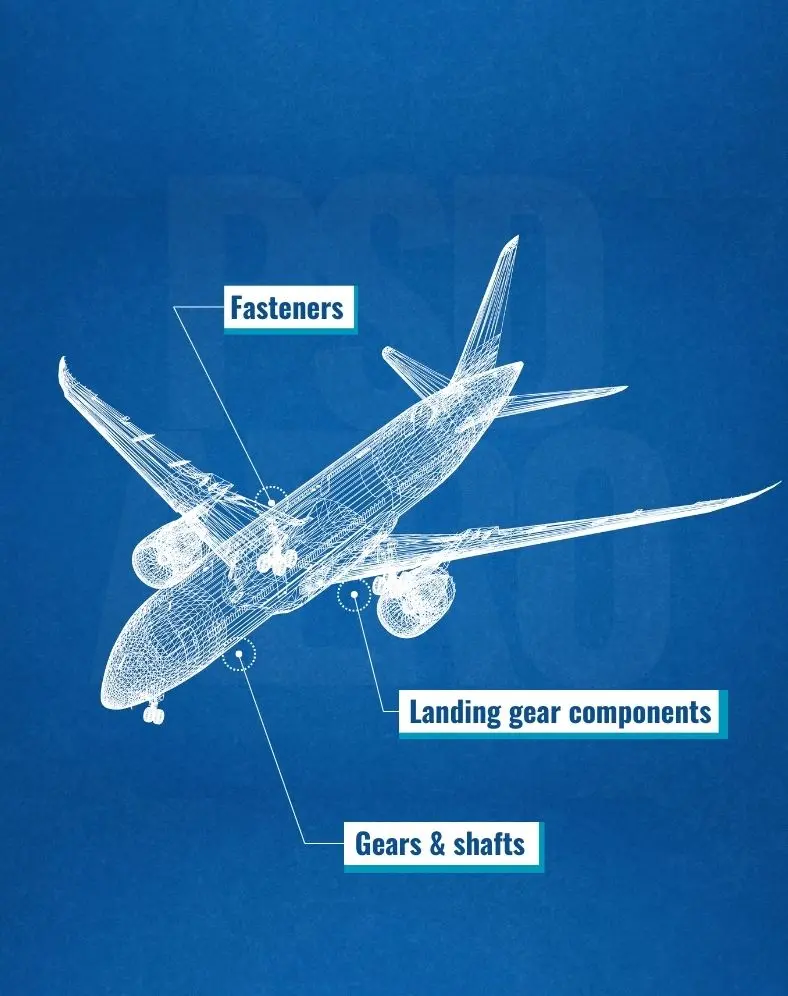

How 17-4PH is used in aerospace

The practical applications of this stainless steel in aircraft construction.

Landing Gear Components

17-4PH steel is used for specific landing gear parts due to its excellent shock absorption capabilities. This alloy reduces the need for corrosion-protection treatments typically required for other high-strength steels.

Gears and Shafts

Transmission shafts, rotor axes, and gears made of 17-4PH benefit from high hardness, ensuring reliability under significant mechanical stress. These properties make it a suitable choice for helicopter rotor hubs and shafts.

Fasteners

17-4PH is commonly used for manufacturing bolts, studs, structural fittings, and fasteners in aircraft and missiles, effectively assembling critical aerospace components.