Aluminum 2014 - AlCu4SiMg - 3.1255 - EN AW-2014

Belonging to the 2000 (aluminum-copper) family, 2014 aluminum is a high-strength alloy primarily composed of 4 to 5% copper, with further additions of silicon and magnesium. It is also known by the designation AlCu4SiMg, or as 2014A under stricter European standards. The alloy is well-regarded for providing exceptional strength combined with excellent machinability.

Available shapes :

Order 2014 Online

Select the desired form, standard, or specification and place your order with one click. A member of our sales team will contact you promptly to finalize your order.

EN/ASTM Standards and Composition

The contents of each element are defined by the main standards: for example, the European standard EN 573-3 sets these limits for EN AW-2014A. The American AA/ASTM standard for alloy 2014 is very close, with slight differences on certain impurity elements: it notably allows a Si content up to 1.2 % and Fe up to 0.7 %, slightly higher than the European limits (Si 0.9 %, Fe 0.5 % max). Hence the designation 2014A in Europe, which defines the same alloy but with tighter specifications. Although the differences between 2014 and 2014A are slight, the latter is preferred for its reliability and predictability under load. For a complete comparison of the compositions, physical and electrical properties — and many others — of each of these alloys, you can refer to this website.

Alloy 2014 corresponds to the standardized designations UNS A92014, Werkstoff Nr. 3.1255 / 3.1254 (former German designations). Historically called duralumin (British codes HE15 or L168) because of its copper content, it was already an improved grade compared with the first duralumin alloys (2017 alloy).

Mechanical Properties and Tempers

The mechanical properties of alloy 2014 vary significantly with its temper. This alloy is heat-treatable by ageing and comes in conditions such as T4, T6, T651, etc.

The T4 temper is obtained after solution quenching and natural ageing; it offers a good strength/ductility compromise for forming operations. This condition provides the greatest ductility but the lowest hardness, which increases with ageing in inverse relation to ductility. Conversely, the T6 treatment (quenched then artificially aged) maximizes strength through structural ageing, at the cost of lower ductility. Finally, the T651 temper is a T6 with stress-relief stretching applied before ageing; this step releases the residual stresses from quenching and gives properties similar to T6 while reducing distortion.

Other conditions are applicable to 2014 but are less common, such as T3 (quenched, cold-worked, then naturally aged) or the annealed O state used for easy machining or forming.

2.1 Physical Properties

Alloy 2014 exhibits the physical properties typical of high-strength aluminum alloys. It is slightly denser than pure aluminum (2.7) while remaining far lighter than steel (about two-thirds less). Its thermal conductivity is two to three times higher than that of steel and is accompanied by a non-negligible thermal expansion (≈ 23 × 10-6/K). The Young’s modulus (70–73 GPa) varies little among aluminum alloys.

2.2 Heat Treatments

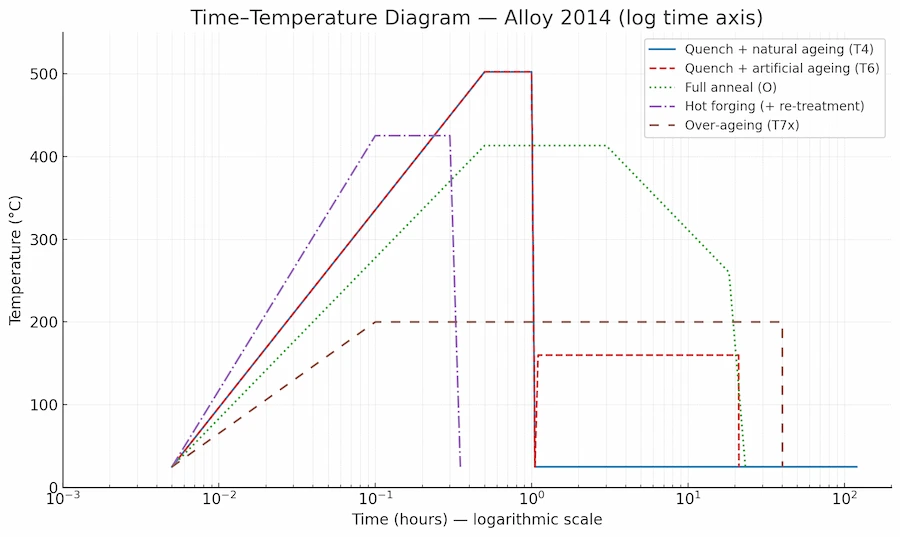

Alloy 2014 is heat-treatable by precipitation hardening; it derives its high performance from the fine precipitation of CuAl2 (θ' phase) during ageing. The standard treatments applied are T4, T6, T651/T6510/T6511, etc., as described above. They and their various steps are shown in the diagram below:

| Color / style | Trajectory | Key points |

|---|---|---|

| Solid blue | Quench + natural ageing (T4) | Heating to ≈ 502 °C, cold-water quench, dwell at 25 °C for ~5 days → natural θ’ precipitation. |

| Dashed red | Quench + artificial ageing (T6) | Same sequence up to quenching, rapid rise to 160 °C for 10–20 h then cooling → fine micro-precipitates, maximum strength. |

| Dotted green | Full anneal (O) | Ramp to 413 °C, hold 2–3 h, very slow cooling (10 °C/h) to 260 °C then air-cool → complete softening for forming. |

| Dash-dot violet | Hot forging | Rapid preheat to about 425 °C, forge, quench or re-treat immediately to return to T6/T7 condition. |

| Long-dash brown | Over-ageing (T7x) | Prolonged hold around 200 °C (~40 h) for dimensional stability / SCC resistance at the expense of strength. |

The choice of temper (T4 vs T6/T651) depends, as noted, on the desired compromise between strength and toughness/ductility and on manufacturing constraints (forming, machining, assembly).

Using 2014 alloy

3.1 Machinability

Alloy 2014 is renowned for its very good machinability. Technical data rank it among the best aluminum alloys for machining, with a rating around 70–80 % (on a scale where 2011 equals 100 %). This translates into high cutting speeds and low tool wear (except in T6). Coolants (light cutting oil or kerosene) are recommended to remove heat and obtain a good finish. On the other hand, the cold formability of 2014 is limited: it cracks more easily in tight bending. It is therefore preferable to resort to hot forming or to the T3/T4 condition for forming operations.

3.2 Weldability

The weldability of alloy 2014 is considered difficult. Fusion welding (TIG/MIG) is generally not recommended. If fusion welding must nonetheless be carried out, strict precautions are required; even so, the risk of solidification cracking remains high. In practice, welded assemblies in alloy 2014 are rare; mechanical fastenings (bolting, riveting) are preferred.

3.3 Corrosion Resistance

Corrosion resistance: this is one of the weak points of alloy 2014. Like many copper-rich alloys, it is not very resistant to atmospheric corrosion. Without adequate protection, 2014 corrodes easily. This susceptibility often justifies the use of the 2014A Alclad version (clad sheet) for critical aerospace applications, as well as the use of surface treatments.

Industrial Applications

Thanks to its excellent combination of strength and machinability, alloy 2014 has found many industrial applications:

- Aerospace and space: a classical alloy for aircraft structures, present in structural aircraft parts (fuselage frames, wing reinforcements).

- Defense and armament: used in various military equipment, e.g. components of armored or military transport vehicles (chassis, suspension elements).

- Automotive (sports) and transport: employed for high-performance components requiring superior strength.

Its use must nevertheless take account of its limitations in corrosion resistance and weldability, which explains why it is often used in protected form (clad, painted) or in a controlled environment.

Chemical composition of 2014

The mini/maxi variations in its chemical composition accepted for aerospace applications.

| % | Cr Chromium | Cu Copper | Fe Iron | Mg Magnesium | Mn Manganese | Si Silicon | Ti Titanium | Zn Zinc |

|---|---|---|---|---|---|---|---|---|

| Min. | <0.00 | 3.90 | <0.00 | 0.20 | 0.40 | 0.50 | <0.00 | <0.00 |

| Max. | 0.10 | 5.00 | 0.70 | 0.80 | 1.20 | 1.20 | 0.15 | 0.25 |

Related aluminum alloys

2014A

RECTANGULAR BAR, ROUND BAR, SHEET (THICKNESS < 6MM)

2017, AlCu4MgSi, AL4

SHEET (THICKNESS < 6MM), SHEET (THICKNESS> 6MM)

2024, AU4G1, 3.1354, EN AW-2024, Al-Cu4Mg1

SQUARE BAR, ROUND BAR, PROFILE, SHEET (THICKNESS < 6MM), SHEET (THICKNESS> 6MM), ROUND TUBE

2050

SHEET (THICKNESS > 6MM)

2219, AlCu6Mn, EN AW-2219

SHEET (THICKNESS > 6MM)

2524

SHEET (THICKNESS < 6MM)

2618, AU2GN, 3.1924, EN AW-AlCu2Mg1,5Ni, AL-P2618A

SHEET (THICKNESS > 6MM), ROUND TUBE

2618A

RECTANGULAR BAR, ROUND BAR, SHEET (THICKNESS > 6MM)

5005, EN AW-5005, EN AW-AlMg1(B)

PERFORATED SHEET

5052, EN AW-5052, EN AW-AlMg2,5, 3.3524, AL-P5052

ROUND TUBE

5086, EN AW-5086, EN AW-AlMg4, 3.3545, AB 5086

ROUND BAR, PROFILE, SHEET (THICKNESS < 6MM), PERFORATED SHEET, ROUND TUBE

5251, 3.3525, EN AW-5251, EN AW-AlMg2, EN AW-AlMgMn0,3

ROUND TUBE

5754, 3.3535, EN AW-5754, EN AW-AlMg3

PERFORATED SHEET

6061, 3.3214, EN AW-6061, EN AW-AlMg1SiCu

ROUND BAR, SHEET (THICKNESS < 6MM), SHEET (THICKNESS> 6MM), ROUND TUBE

6063

SHEET (THICKNESS < 6MM)

6082

ROUND BAR

7010

SHEET (THICKNESS > 6MM)

7010-7050

SHEET (THICKNESS > 6MM)

7050

ROUND BAR, PROFILE, SHEET (THICKNESS > 6MM), ROUND TUBE

7055

SHEET (THICKNESS < 6MM), SHEET (THICKNESS> 6MM)

7075

RECTANGULAR BAR, ROUND BAR, PROFILE, SHEET (THICKNESS < 6MM), SHEET (THICKNESS> 6MM), ROUND TUBE

7075-7175

ROUND BAR

7150

RECTANGULAR BAR

7175

ROUND BAR, PROFILE, SHEET (THICKNESS > 6MM)

7449

SHEET (THICKNESS > 6MM)

7475

SHEET (THICKNESS < 6MM), SHEET (THICKNESS> 6MM)

CALE PELABLE

SHEET

L56

ROUND TUBE

Key properties

The most remarkable properties of this aluminum alloy.

Thermal capacity

869 J/(kg·°C)

Thermal conductivity

134–200 W/(m·°C)

Tensile Strength

≥ 220 MPa

Brinell Hardness

45–140 HB