Aluminum 5754 - 3.3535 - EN AW-5754 - EN AW-AlMg3

Aluminum alloy 5754 (AlMg3) is suitable for structures requiring high strength without heat treatment. A good compromise between 5052 and 5083, it is widely used in the automotive and marine industries. It offers excellent resistance to seawater corrosion (Class A) and welds well without weakening the structure. While machining can be tricky due to its gummy texture, it is easy to form, especially in its “stabilized” tempers (H22/H24).

Available shapes :

Order 5754 Online

Select the desired form, standard, or specification and place your order with one click. A member of our sales team will contact you promptly to finalize your order.

Alloy 5754 (Al-Mg3): an industrial standard

Aluminum EN AW-5754 belongs to the Al-Mg alloy family (5xxx series). Not heat-treatable, it derives its performance from its chemical composition and its work hardening. This grade stands out for a precise balance: high mechanical properties for its category, combined with excellent weldability.

Its main strength remains its resistance in harsh environments. It offers superior resistance to atmospheric corrosion and, more specifically, to seawater, making it a material of choice for the marine and offshore segments.

An automotive legacy: from Panhard to Jaguar

The use of 5754 in automotive structures is nothing new. The industry identified it early for its ability to combine lightness with structural strength.

- The pioneers (1953) : The alloy (then designated AG3) enabled mass production of the famous Panhard Z1, illustrating the early use of “ Duralinox ” sheets for the bodywork (European Aluminium).

- Structural evolution (1998) : Ford validated its use for body-in-white structures with the P2000 prototype, using 5754 in the annealed condition.

- The modern era (2016) : The aluminum giant Novelis continues to evolve this “ original alloy ”. In partnership with Jaguar Land Rover (notably for the Jaguar XE), it developed recycled variants (RC5754).

See designations and technical equivalents (ISO/DIN)

| Standard | Designation |

|---|---|

| EN (numeric) | EN AW-5754 |

| EN (chemical) | EN AW-Al Mg3 |

| Werkstoff-Nr. (DIN) | 3.3535 |

Influence of chemical composition

The performance of 5754 relies on precise control of alloying elements. While magnesium dictates the main properties, secondary elements play a crucial role in stabilizing the structure and corrosion resistance. The mechanisms below are documented by ASM International / NIST.

Magnesium (Mg), the main addition and the driver of strength

In the 5xxx series, magnesium is the primary alloying element. It provides mechanical strengthening by solid-solution strengthening and increases the alloy’s work-hardening capacity.

Corrosion note : As long as magnesium remains in solid solution, corrosion resistance is comparable to that of pure aluminum. However, an Mg content above 3 % can lead to sensitization to intergranular corrosion or stress corrosion cracking (SCC) if precipitates form continuously along grain boundaries. 5754 is optimized (chemistry and tempers) to prevent this risk.

Manganese (Mn) and chromium (Cr) control the structure

These elements act as structure modifiers :

- Manganese : It strengthens the matrix and controls grain size during recrystallization. Unlike other strengthening elements, it does not impair the alloy’s corrosion resistance.

- Chromium : Present in small amounts, it forms fine precipitates that prevent excessive grain growth, with no detrimental effect on chemical resistance.

- Titanium : Used mainly for grain refinement during casting (often via Al-Ti-B master alloys).

Critical impurities (Fe, Cu)

Impurity control is essential to maintain performance in marine environments :

- Iron (Fe) : In the presence of silicon, it forms intermetallic phases that are cathodic relative to the matrix. These “ local galvanic cells ” can initiate pitting corrosion in conductive environments.

- Copper (Cu) : Although it is the basis of 2xxx alloys (aerospace), copper is undesirable here. Its presence reduces general corrosion resistance through cathodic redeposition.

See intermetallic phases and mechanisms (technical details)

Precipitation phases and dispersoids :

- Al-Mg system : Excess Mg can precipitate as the β phase (Al8Mg5). A continuous distribution along grain boundaries is the risk factor for exfoliation corrosion or SCC.

- Manganese (Mn) : Combines to form dispersoids such as Al6(Mn,Fe) or Al12(Fe,Mn)3Si.

- Chromium (Cr) : Forms submicroscopic precipitates Al12Mg2Cr.

- Iron (Fe) : Responsible for phases Al3Fe or Al6Fe (cathodic).

- Silicon (Si) : Can interact with Mg to form Mg2Si (the basis of hardening in the 6xxx series), changing the mechanical response.

Source of metallurgical data : Aluminum and Aluminum Alloys (Davis/NIST).

Tempers and heat treatments

⚠️ Fundamental point : 5754 is a non heat-treatable alloy. Unlike the 6xxx or 7xxx series, it does not harden by heat treatment. Its strengthening is obtained only by work hardening (cold work / deformation).

Decoding the “ H ” tempers (Hardened)

The designation of a strain-hardened temper consists of the letter H followed by two (or three) digits.

Example : H24 = strain hardened and partially annealed (2) + half-hard (4).

The 1st digit: the process

- H1x (strain hardened only) :

The metal is hardened by rolling with no subsequent heat treatment. - H2x (strain hardened + partial anneal) :

The material is work-hardened more than necessary, then a “ partial anneal ” is performed to bring it back down to the target strength.

Benefit : better elongation than H1x at equal strength. - H3x (stabilized) :

Specific to Al-Mg (5xxx) alloys. A hold at moderate temperature prevents the “ natural softening ” that occurs over time in these alloys.

The 2nd digit: final hardness

This digit indicates the strength level relative to the hardest temper (H8).

| Hx2 | Quarter-hard (1/4 hard) |

| Hx4 | Half-hard (1/2 hard) |

| Hx6 | Three-quarter hard (3/4 hard) |

| Hx8 | Hard |

| Hx9 | Extra-hard (rare, Rm > Hx8 + 14 MPa) |

Source (definitions) : ASM / NIST.

Common special cases: H111 and H112

| Temper | Technical definition | Practical use |

|---|---|---|

| H111 | Annealed followed by very slight strain hardening (leveling). | This is the “ standard ” temper for flat sheet that needs to be bent easily. Nearly equivalent to the O temper (annealed). |

| H112 | As hot-worked (with no controlled cold work or subsequent controlled anneal). | Typical for thick products (extruded tubes or bars), where a minimum strength is guaranteed without controlling a precise hardness level. |

Temperature guide

Although it is not quench-hardenable, 5754 responds to recrystallization heat treatments (annealing).

Recrystallization anneal (full anneal)

- Temperature : 360 °C to 380 °C

- Time : 1 to 2 hours (through-thickness)

- Cooling : slow / uncontrolled (furnace)

- Goal : mechanical reset. Brings the metal back to temper O (soft) after excessive work hardening.

≈ 345 °C (air cooling). To remove internal stresses without necessarily fully recrystallizing.

205 °C to 370 °C. Ideal range for heavy plastic deformation.

Sources (temperatures) : Bikar & Yieh Corp.

Mechanical properties of aluminum 5754

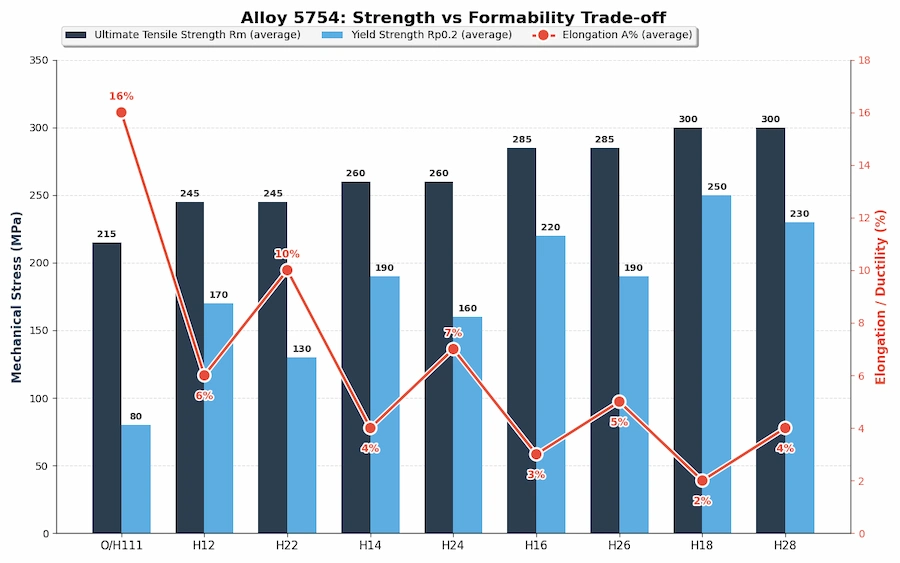

Mechanical performance depends on the product form (sheet or bar) and the temper. The chart below summarizes the key trade-off : the H2x series offers better ductility than the H1x series at equal strength.

Sheets (NF EN 485-2)

Click the temper below to see the corresponding characteristics :

Temper O / H111 (annealed – ideal for bending)

| Thickness (mm) | Rm (MPa) | Rp0,2 (MPa) | A % (min.) | Bending radius (90°) | Hardness HBS |

|---|---|---|---|---|---|

| 0,2 à 0,5 | 190 - 240 | 80 (min.) | 12 | 0 e | 52 |

| 0,5 à 1,5 | 190 - 240 | 80 (min.) | 14 | 0,5 e | 52 |

| 1,5 à 3,0 | 190 - 240 | 80 (min.) | 16 | 1,0 e | 52 |

| 3,0 à 6,0 | 190 - 240 | 80 (min.) | 18 | 1,0 e | 52 |

| 6,0 à 12,5 | 190 - 240 | 80 (min.) | 18 | 2,0 e | 52 |

| 12,5 à 100 | 190 - 240 | 80 (min.) | 17 | - | 52 |

Tempers H12, H22, H32 (1/4 hard)

H12 (strain hardened by rolling)

| Thickness (mm) | Rm (MPa) | Rp0,2 (MPa) | A % | Hardness HBS |

|---|---|---|---|---|

| 0,2 à 0,5 | 220 - 270 | 170 | 4 | 66 |

| 0,5 à 1,5 | 220 - 270 | 170 | 5 | 66 |

| 1,5 à 3,0 | 220 - 270 | 170 | 6 | 66 |

| 3,0 à 12,5 | 220 - 270 | 170 | 7-9 | 66 |

H22 / H32 (strain hardened and stabilized – more ductile than H12)

| Thickness (mm) | Rm (MPa) | Rp0,2 (MPa) | A % | 90° radius | Hardness HBS |

|---|---|---|---|---|---|

| 0,2 à 0,5 | 220 - 270 | 130 | 7 | 0,5 e | 63 |

| 0,5 à 1,5 | 220 - 270 | 130 | 8 | 1,0 e | 63 |

| 1,5 à 3,0 | 220 - 270 | 130 | 10 | 1,5 e | 63 |

| 3,0 à 6,0 | 220 - 270 | 130 | 11 | 1,5 e | 63 |

Tempers H14, H24, H34 (1/2 hard)

H14

| Thickness | Rm (MPa) | Rp0,2 | A % | Hardness HBS |

|---|---|---|---|---|

| 0,2 à 3,0 | 240 - 280 | 190 | 3-4 | 72 |

| 3,0 à 12,5 | 240 - 280 | 190 | 4-5 | 72 |

H24 / H34

| Thickness | Rm (MPa) | Rp0,2 | A % | 90° radius | Hardness HBS |

|---|---|---|---|---|---|

| 0,2 à 1,5 | 240 - 280 | 160 | 6 | 1,0 e - 1,5 e | 70 |

| 1,5 à 3,0 | 240 - 280 | 160 | 7 | 2,0 e | 70 |

| 3,0 à 6,0 | 240 - 280 | 160 | 8 | 2,5 e | 70 |

Tempers H16, H18, H26... (hard)

| Temper | Thickness | Rm (MPa) | Rp0,2 | A % | Hardness HBS |

|---|---|---|---|---|---|

| H16 | 0,2 à 6,0 | 265 - 305 | 220 | 2-3 | 80 |

| H18 | 0,2 à 3,0 | 290 (min.) | 250 | 1-2 | 88 |

| H26/36 | 0,2 à 6,0 | 265 - 305 | 190 | 4-6 | 78 |

| H28/38 | 0,2 à 3,0 | 290 (min.) | 230 | 3-4 | 87 |

Source : Reynolds European (sheets).

Bars and tubes (NF EN 754-2 / 755-2)

Select the product type to see the characteristics :

BARS (Round, Square, Hex, Flat)

DRAWN bars (calibrated – more precise & harder)

| Temper | Shape & size | Rm (MPa) | Rp0,2 | A % | Hardness HBW |

|---|---|---|---|---|---|

| O / H111 (annealed) | Round ≤ 80 mm | 180 - 250 | ≥ 80 | 16 | 45 |

| Square/Hex ≤ 60 mm | |||||

| H14 / H24 (half-hard) | Round ≤ 25 mm | 240 - 290 | ≥ 180 | 4 | 75 |

| Square/Hex ≤ 5 mm | |||||

| H18 / H28 (hard) | Round ≤ 10 mm | ≥ 280 | ≥ 240 | 3 | 88 |

| Square/Hex ≤ 3 mm |

EXTRUDED bars (standard – extruded)

| Temper | Size (mm) | Rm (MPa) | Rp0,2 | A % | Hardness HBW |

|---|---|---|---|---|---|

| F / H112 (as fabricated) | ≤ 150 mm | ≥ 180 | ≥ 80 | 14 | 47 |

| F / H112 (large diameter) | 150 < Ø ≤ 250 | ≥ 180 | ≥ 70 | 13 | 47 |

| O / H111 (annealed) | ≤ 150 mm | 180 - 250 | ≥ 80 | 17 | 45 |

TUBES & PROFILES

| Type | Temper | Wall thickness | Rm (MPa) | Rp0,2 | Hardness |

|---|---|---|---|---|---|

| DRAWN tube (calibrated) | O / H111 | ≤ 20 mm | 180 - 250 | ≥ 80 | 45 |

| H14 / H24 | ≤ 10 mm | 240 - 290 | ≥ 180 | 75 | |

| H18 / H28 | ≤ 3 mm | ≥ 280 | ≥ 240 | 88 | |

| EXTRUDED tube | F / H112 | ≤ 25 mm | ≥ 180 | ≥ 80 | 47 |

| Profile | F / H112 | ≤ 25 mm | ≥ 180 | ≥ 80 | 47 |

Note : for drawn H18 tubes, elongation is very low (2-3 %).

Source : Bikar (long products).

Corrosion resistance of a “ marine ” standard

Alloy 5754 is rated category A (Excellent) by reference guides (such as the AFSA guide). Its specific chemistry gives it very good resistance to seawater and industrial atmospheres.

The structural advantage

In most environments (even in marine immersion), no protective coating is required to ensure the part’s structural integrity. Painting or anodizing becomes necessary only for aesthetic (architectural) reasons or in extreme environments (C5+).

Performance by environment type (ISO 9223)

Here are the standard recommendations for 5754 sheets (tempers O/H22/H24/H26) :

| Environment (ISO) | Example | Protection needed ? |

|---|---|---|

| C1 / C2 / C3 | Rural, urban, light industrial | NO |

| C4 / Marine | Coastal areas, splash zones | NO |

| Immersion | Seawater | NO |

| C5 / C5+ | Very aggressive industrial / offshore | Optional (P) Recommended if aesthetics are critical |

Marine certification criteria (ASTM tests for classification)

For a batch of 5754 to be certified for naval use (e.g. : Bureau Veritas), it must pass specific accelerated corrosion tests aimed at detecting intergranular (IGC) or exfoliation sensitization.

- IGC resistance (ASTM G67 - NAMLT) :

Nitric acid mass-loss test (24 h at 30 °C).

✔ Pass criterion : Mass loss ≤ 15 mg/cm². - Exfoliation resistance (ASTM G66 - ASSET) :

Visual rating after immersion.

✔ Pass criterion :PB (Pitting B) or better.

Note : any trace of exfoliation (ratings EA to ED) is disqualifying.

Criteria source : Bureau Veritas Rules (NR 216).

Processing: forming, welding, and machining

| Parameter | Indicator (source) | Industrial interpretation |

|---|---|---|

| Formability | n=0.37 (high) Source | Excellent. Resists tearing during stretch forming. Ideal for automotive panels – AA5754-O, sheet. |

| Anisotropy | Δr=0.286 Source | Moderate. Allow for “ earing ” (uneven edges) in deep drawing. |

| Machining | Tool impact > speed Source | Difficult finish. “ Gummy ” behavior. Requires coated/polished tools to avoid built-up edge – AA5754-H111, specimen. |

| Joining | Efficiency 88 % Source | Very good. Does not suffer severe softening of the heat-affected zone (HAZ) like 6082/6061 – AA5754-H22, sheet. |

Positioning versus alternatives (5052, 5083, 5182)

Within the Al-Mg alloy family, selection is driven by magnesium content. 5754 (AlMg3) sits at the balance point : stronger than the 5052 standard, but more stable and versatile than “ heavy ” alloys such as 5083.

| Parameter | 5052 (AlMg2.5) | 5754 (AlMg3) | 5083 (AlMg4.5) | 5182 (AlMg4.5Mn) |

|---|---|---|---|---|

| Magnesium (wt.%) | 2,2 – 2,8 | 2,6 – 3,6 | 4,0 – 4,9 | 4,0 – 5,0 |

| Rp0,2 (O/H111) | 65 MPa | 80 MPa | ≥ 125 MPa | 110 MPa |

| Rm (ultimate) (O/H111) | 170–215 MPa | 190–240 MPa | 275–350 MPa | 255–315 MPa |

| Temper H22 (¼ hard) | Rp0,2 : 130 MPa A50 : 7 % | Rp0,2 : 130 MPa A50 : 10 % | Rp0,2 : ≥215 MPa A50 : ≥7 % | N/A (rare) |

| Durability (Eurocode 9) | A | A | A1 (heat-sensitive) | - |

| Typical applications | General use, simple bending | Automotive structures, marine | Heavy marine, armor | Body panels (skin), cans |

Source : Eurocode 9 (Table 3.1a/C.1), European Aluminium.

Chemical composition of 5754

The mini/maxi variations in its chemical composition accepted for aerospace applications.

| % | Be Beryllium | Cr Chromium | Cu Copper | Fe Iron | Mg Magnesium | Mn Manganese | Si Silicon | Ti Titanium | Zn Zinc |

|---|---|---|---|---|---|---|---|---|---|

| Min. | 0.00 | 0.00 | 0.00 | 0.00 | 2.60 | 0.00 | 0.00 | 0.00 | 0.00 |

| Max. | 0.0003 | 0.30 | 0.10 | 0.40 | 3.60 | 0.50 | 0.40 | 0.15 | 0.20 |

Related aluminum alloys

2014, AlCu4SiMg, 3.1255, EN AW-2014

SHEET (THICKNESS < 6MM)

2014A

RECTANGULAR BAR, ROUND BAR, SHEET (THICKNESS < 6MM)

2017, AlCu4MgSi, AL4

SHEET (THICKNESS < 6MM), SHEET (THICKNESS> 6MM)

2024, AU4G1, 3.1354, EN AW-2024, Al-Cu4Mg1

SQUARE BAR, ROUND BAR, PROFILE, SHEET (THICKNESS < 6MM), SHEET (THICKNESS> 6MM), ROUND TUBE

2050

SHEET (THICKNESS > 6MM)

2219, AlCu6Mn, EN AW-2219

SHEET (THICKNESS > 6MM)

2524

SHEET (THICKNESS < 6MM)

2618, AU2GN, 3.1924, EN AW-AlCu2Mg1,5Ni, AL-P2618A

SHEET (THICKNESS > 6MM), ROUND TUBE

2618A

RECTANGULAR BAR, ROUND BAR, SHEET (THICKNESS > 6MM)

5005, EN AW-5005, EN AW-AlMg1(B)

PERFORATED SHEET

5052, EN AW-5052, EN AW-AlMg2,5, 3.3524, AL-P5052

ROUND TUBE

5086, EN AW-5086, EN AW-AlMg4, 3.3545, AB 5086

ROUND BAR, PROFILE, SHEET (THICKNESS < 6MM), PERFORATED SHEET, ROUND TUBE

5251, 3.3525, EN AW-5251, EN AW-AlMg2, EN AW-AlMgMn0,3

ROUND TUBE

6061, 3.3214, EN AW-6061, EN AW-AlMg1SiCu

ROUND BAR, SHEET (THICKNESS < 6MM), SHEET (THICKNESS> 6MM), ROUND TUBE

6063

SHEET (THICKNESS < 6MM)

6082

ROUND BAR

7010

SHEET (THICKNESS > 6MM)

7010-7050

SHEET (THICKNESS > 6MM)

7050

ROUND BAR, PROFILE, SHEET (THICKNESS > 6MM), ROUND TUBE

7055

SHEET (THICKNESS < 6MM), SHEET (THICKNESS> 6MM)

7075

RECTANGULAR BAR, ROUND BAR, PROFILE, SHEET (THICKNESS < 6MM), SHEET (THICKNESS> 6MM), ROUND TUBE

7075-7175

ROUND BAR

7150

RECTANGULAR BAR

7175

ROUND BAR, PROFILE, SHEET (THICKNESS > 6MM)

7449

SHEET (THICKNESS > 6MM)

7475

SHEET (THICKNESS < 6MM), SHEET (THICKNESS> 6MM)

CALE PELABLE

SHEET

L56

ROUND TUBE

Key properties

The most remarkable properties of this aluminum alloy.

Thermal capacity

897 J/(kg·°C)

Thermal conductivity

132–160 W/(m·°C)

Density

2.66–2.68 kg/dm³

Tensile Strength

180–310 MPa